Kompac & Tecnau Partnership Printing United Expo 2023

Kompac & Tecnau: A Powerful Partnership Redefining Printing Solutions at PRINTING United Expo

At Booth B2806 in the PRINTING United Expo, Kompac and Tecnau join forces in a groundbreaking display of first-time exhibitions, showcasing the strength of their collaborative efforts. The spotlight of Tecnau's exhibit is the Stack 1212 cut/stack line, seamlessly integrated with the Kompac Phoenix 20S Coater. This dynamic duo is tailored for B2/B2+ sheets and represents Tecnau's market-leading portfolio of production finishing solutions.

The Phoenix 20S coater flood coats and feeds sheets to Tecnau's Stack 1212, which, in a single pass, cross cuts, removes gutters and side trims, presenting finished, coated postcards stacked on the exit conveyor. This innovative process eliminates the need for manual substrate handling, supporting up to 21-up impositions and paper weights up to 350 gsm at speeds of up to 6000 input sheets per hour. The Stack 1212 is versatile, capable of cutting postcards, letters, books, brochures, and calendars down to size.

Key Features of the Kompac/Tecnau Line

Small Footprint: The joint Kompac/Tecnau line takes up significantly less space than competitive offerings, making it a practical choice for environments where space is at a premium.

Offline Configuration: Depending on the application environment, users have the flexibility to support coating, cutting, and trimming output from multiple digital and offset presses, enhancing overall operational efficiency.

Economical Operation: The integration of Kompac's Phoenix 20 S Coater and Tecnau's Stack 1212 ensures a simple and intuitive operation, eliminating manual processes and contributing to a cost-effective workflow.

Meet Thomas Hayes, the President of Kompac Technologies

At the forefront of technological advancement in the printing industry is Thomas Hayes, the President of Kompac Technologies. Specializing in both water- and UV-based coaters, Kompac is pushing the boundaries of what's possible in the ever-evolving world of print finishing. One standout demonstration of their prowess is at the Tecnau booth, where they unveil an inline/nearline solution for online coating—an ingenious concept that aligns seamlessly with the evolving landscape of digital printing.

Thomas Hayes and the Kompac team shine a spotlight on the future of print finishing with their inline/nearline coating solution showcased at the Tecnau booth. This forward-thinking approach addresses the increasing quality of digital print, predicting a shift of more applications to the digital realm. The integrated solution presented by Tecnau and Kompac emerges as a strategic response to this industry evolution.

As digital print technology continues to advance, Thomas Hayes emphasizes the growing trend of applications migrating to digital platforms. The Tecnau and Kompac collaboration anticipates and embraces this evolution by offering integrated solutions tailored to the changing needs of the industry. Whether it's postcards, covers, or any other application, the synergy between Tecnau and Kompac presents a streamlined and efficient solution for the digital age.

The Phoenix

The Phoenix coating system stands as a pinnacle of unmatched flexibility. Available in 20” or 30”, the Phoenix providing a spectrum of configuration options, including both in-line and nearline setups, as well as the choice between simplex and duplex modes. Its ingenious modular design bestows customers with the liberty to fine-tune the equipment to impeccably align with their specific business requirements. This exceptional adaptability positions the Phoenix as the go-to solution for businesses keen on optimizing their operational efficiency.

Crafted with precision and efficiency as guiding principles, the Phoenix guarantees a seamless and high-quality performance on every occasion. The equipment's user-friendly interface and hassle-free maintenance further contribute to its allure, ensuring minimal downtime and, in turn, maximizing productivity. In essence, the Phoenix is not just a coating system; it's a tailored, precision-engineered solution poised to elevate and streamline operations for businesses aiming for excellence

Genuine Kompac Parts for Repairing & Maintaining Your Coater

Pictured: Phoenix 20 Purple Form Roller

When it comes to the repair and maintenance of your Kompac coater, it is essential to invest in genuine Kompac technology parts rather than opting for used parts that are not manufactured by Kompac. Genuine parts offer numerous advantages, including superior quality, compatibility, reliability, and long-term cost-effectiveness. In this article, we delve into why it is better to choose genuine Kompac technology parts for your repair and maintenance needs.

Unmatched Quality and Performance

Genuine Kompac technology parts are designed and manufactured to the highest standards, ensuring uncompromised quality and exceptional performance. Kompac invests significant resources in research and development to innovate and refine their products continually. By purchasing genuine parts, you can rest assured that you are receiving components specifically engineered for your Kompac coater, which ensures optimal functionality and longevity.

Pictured: Phoenix 20/30 Hybrid Chamber Drain Hose Kit

Perfect Compatibility & Fit

Choosing genuine Kompac technology parts guarantees a seamless fit and compatibility with your coater. These parts are meticulously designed to integrate flawlessly with the existing components, ensuring proper alignment and operation. On the other hand, non-genuine or used parts may not adhere to the same stringent specifications, resulting in compatibility issues, compromised performance, and potential damage to your coater.

Enhanced Reliability & Durability

Genuine Kompac technology parts undergo rigorous testing and quality control procedures to ensure their durability and reliability. By using authentic parts, you reduce the risk of premature failures, breakdowns, and unscheduled downtime. The superior craftsmanship and materials used in genuine parts contribute to their longevity and resistance to wear and tear. Investing in reliable components ultimately translates into improved productivity, reduced maintenance costs, and increased customer satisfaction.

Comprehensive Warranty & Support

Purchasing genuine Kompac technology parts provides the added advantage of comprehensive warranty coverage and access to professional support. In the unlikely event of a malfunction or defective part, Kompac stands behind their products and offers assistance and replacement options. With non-genuine or used parts, you may not have any recourse if issues arise, leaving you to shoulder the cost and inconvenience of resolving the problem independently.

Pictured: Phoenix 20 Backing Plate Kit

Long-Term Cost-Effectiveness

While the initial cost of genuine Kompac technology parts may be slightly higher than non-genuine alternatives, their long-term cost-effectiveness becomes apparent. Genuine parts offer superior quality, compatibility, and durability, leading to reduced maintenance expenses and downtime. Choosing genuine components eliminates the risks associated with substandard parts, such as additional repairs, rework, and potential damage to other components. In the end, investing in genuine Kompac technology parts proves to be a wise decision for your coater’s overall performance and your budget.

When it comes to repairing or maintaining your Kompac coater, choosing genuine Kompac technology parts is an investment in quality, performance, and long-term reliability. These parts are specifically engineered to meet the highest standards, ensuring perfect compatibility and fit, enhanced durability, and optimal performance. While non-genuine or used parts may seem like a cost-saving option initially, they often lead to compromised functionality, increased downtime, and higher overall expenses. By prioritizing genuine Kompac technology parts, you safeguard the integrity of your coater and ensure its continued efficiency for years to come.

Kompac Technologies Sapphire Primer: The Unparalleled Choice for Priming Excellence

Pictured: Kompac Komplete Sapphire 10.0 Primer

When it comes to achieving flawless prints and maximizing the potential of your printing projects, a reliable and high-quality primer is essential. Kompac Technologies, a renowned name in the printing industry, has introduced its revolutionary Sapphire Primer, setting new standards for priming solutions. This article will explore why Kompac Technologies’ Sapphire Primer stands out as the best choice for priming, delivering exceptional results and ensuring unmatched printing excellence.

Superior Adhesion

Kompac Technologies Sapphire Primer boasts an advanced formulation designed to enhance adhesion between the substrate and the ink. This results in improved ink transfer, reduced dot gain, and superior image sharpness. The primer creates a smooth, even surface that enables ink to adhere better, resulting in vibrant, accurate colors and sharper details.

Pictured: Kompac Komplete Sapphire 5.0 Primer - 5 Gallon

Versatility

The Sapphire Primer is incredibly versatile, accommodating a wide range of printing applications. It works flawlessly with various substrates, including paper, cardstock, plastics, and even non-porous materials like metal and glass. This versatility makes it the go-to choice for diverse printing projects, offering convenience and flexibility to print professionals across different industries.

Time & Cost Efficiency

One of the key advantages of using Kompac Technologies’ Sapphire Primer is its ability to streamline the printing process. With its quick-drying properties, it significantly reduces the waiting time between priming and printing, enabling faster production cycles. This not only saves valuable time but also translates into cost savings for businesses, as it allows for increased productivity and reduced labor costs.

Consistency & Durability

The Sapphire Primer ensures consistent and reliable results, print after print. Its exceptional durability ensures that the primed surface remains intact throughout the printing process, eliminating issues like ink smudging or smearing. By maintaining consistency and durability, this primer offers unmatched print quality and longevity, allowing your prints to stand the test of time.

Pictured: Kompac Komplete Sapphire 5.0 Primer - 1 Gallon

Environmental Friendliness

In addition to its remarkable performance, Kompac Technologies Sapphire Primer is committed to sustainability. The primer is formulated with environmentally friendly components, minimizing its impact on the ecosystem. It adheres to stringent environmental regulations and reduces waste, making it an excellent choice for environmentally conscious print professionals and businesses.

Kompac Technologies Sapphire Primer has revolutionized the priming industry, offering an unmatched solution for achieving outstanding print quality and maximizing the potential of various printing applications. With its superior adhesion, versatility, time and cost efficiency, consistency, durability, and commitment to sustainability, this primer has set new benchmarks for priming excellence. Whether you’re a professional print service provider, packaging manufacturer, or creative enthusiast, choosing Kompac Technologies’ Sapphire Primer guarantees exceptional results, elevating the quality of your prints to new heights. Invest in the best and experience the difference with Sapphire Primer by Kompac Technologies.

Introducing the New Kompac Technologies Online Store: Your One-Stop Shop for All Kompac Products

In the fast-paced world of printing and coating technologies, finding a reliable source for genuine products and replacement parts is crucial. Look no further than the new Kompac Technologies Online Store, where you’ll discover an extensive range of Kompac products, including UV and AQ coatings, genuine Kompac tools, and reliable replacement parts. With our commitment to quality and customer satisfaction, Kompac Technologies has established itself as a trusted name in the industry, and their new online store is set to revolutionize the way professionals source their printing and coating needs.

Cutting-Edge Products

The Kompac Technologies Online Store offers an array of cutting-edge products that cater to the diverse requirements of the printing and coating industry. Whether you’re in search of UV coatings that add a glossy finish and enhance durability or AQ coatings for a wonderful soft touch finish, this one-stop shop has got you covered. Kompac Technologies understands the importance of delivering high-quality coatings that meet stringent industry standards. By offering their own range of coatings, they ensure that customers receive the genuine article directly from the source, guaranteeing optimal performance and outstanding results.

In addition to our exceptional coatings, the Kompac Technologies Online Store proudly presents genuine Kompac tools. These tools are designed and manufactured by experts who possess an in-depth understanding of the unique challenges faced by printing and coating professionals. From doctor blades to roller covers, these tools are essential for maintaining the longevity and efficiency of Kompac equipment. By providing genuine Kompac tools, the online store ensures that customers have access to the very best resources for their specific needs.

No More Downtime

Moreover, the Kompac that equipment downtime can be costly and disruptive. That’s why they offer a comprehensive selection of genuine Kompac replacement parts. By using authentic Kompac replacement parts, customers can maintain the integrity of their equipment and extend its lifespan. Whether you require replacement rollers, motors, or other critical components, the online store has an extensive inventory to meet your needs. Rest assured that these replacement parts are manufactured with the same precision and expertise that has made Kompac Technologies an industry leader.

What sets the Kompac Store apart from its competitors is the company’s unwavering commitment to customer satisfaction. They prioritize delivering a seamless online shopping experience, providing detailed product descriptions, user-friendly navigation, and secure payment options. The store is designed to cater to the needs of professionals in the printing and coating industry, ensuring that customers can easily find the products and parts they require without any hassle.

Furthermore, the Kompac Store offers dedicated customer support to address any inquiries or concerns. Our knowledgeable team is readily available to assist customers, providing expert advice and guidance when selecting the right products or troubleshooting issues. Kompac Technologies values our customers and strives to foster long-lasting relationships built on trust and reliability.

The Kompac Store is a game-changer for professionals in the printing and coating industry. With its wide range of genuine Kompac products, including UV and AQ coatings, genuine Kompac tools, and reliable replacement parts, the store has become the go-to destination for all your printing and coating needs. By offering direct access to high-quality products and outstanding customer support, Kompac Technologies reaffirms its position as a leading name in the industry. Experience the convenience and excellence of the Kompac Technologies Online Store today and unlock a new level of printing and coating possibilities.

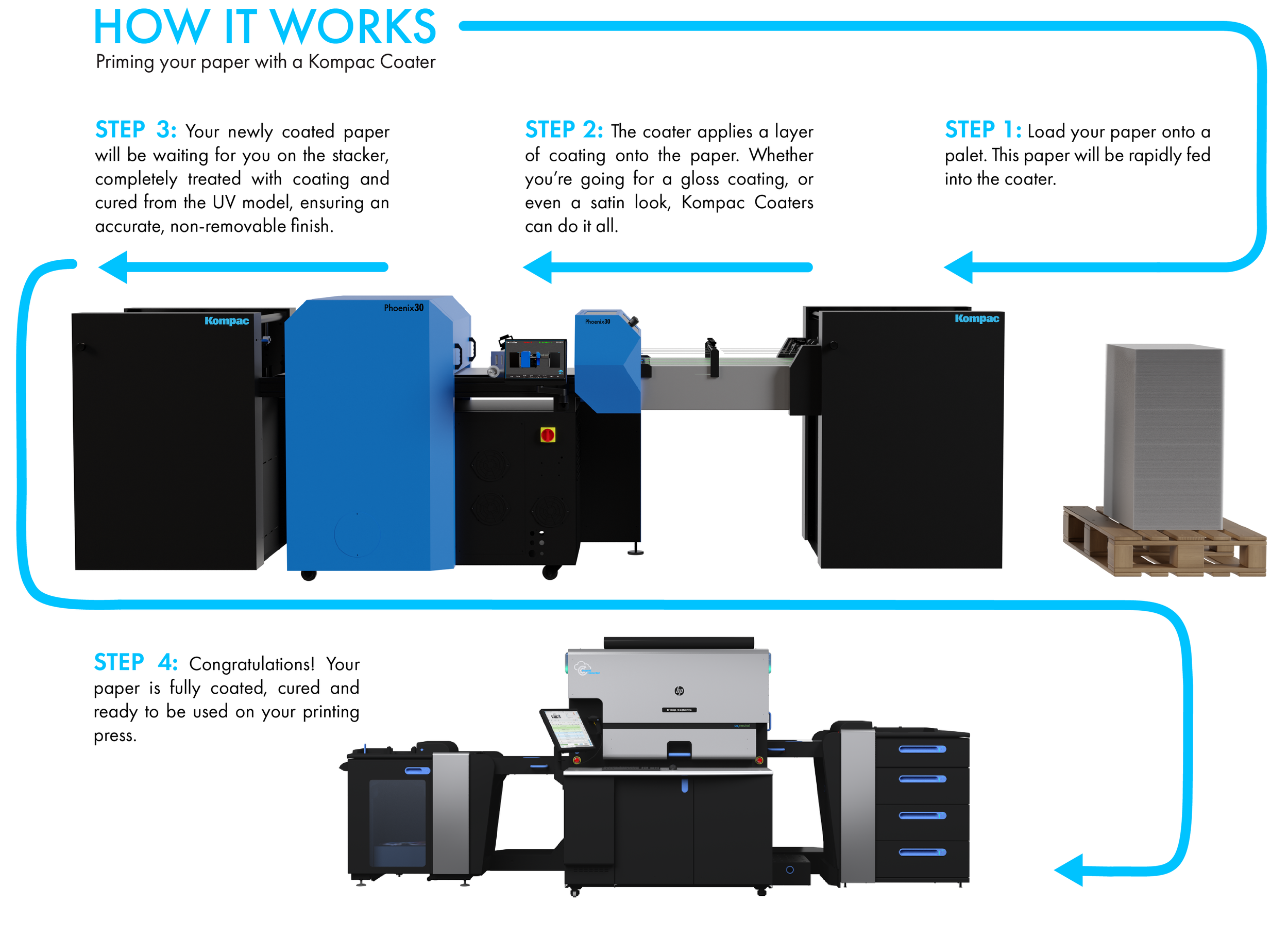

Short on paper? Prime it yourself!

Pictured: Kompac Phoenix 30 S sheet-fed with feeder and stacker.

Paper shortages can be a painful reality for printing companies. The current paper shortage can hit these companies hard, and, in most cases, it is out of the companies’ control. For the duration of the pandemic and even now, the weakening of the global supply chain means that these shortages of resources such as paper aren't going to go away anytime soon. This correlating to the rising price of timber has affected the paper industry harshly. The shortage of paper is creating a large issue right now for those in the paper industry, because acquiring paper with a specialized coating is becoming exceedingly rare, not to mention specific dimensions of paper being outright impossible to acquire. This has led to drastic changes in what size paper can be used for printing in bulk. With the demand for paper being so high now, it’s making more and more sense for paper distributors to look towards alternatives when it comes to making specifically coated paper in house, rather than outsourcing it elsewhere. What if there was a way to have your own paper treated with primer, without having it ever leaving the building?

A proper coating can enhance the appearance and durability, increasing the printed product’s value. Kompac offers a wide range of coaters that can prime your already existing paper, saving you time and money. The Phoenix is just one of the several specialized Kompac coaters that can help you during this paper shortage. Available in 20” (508 mm) & 30” (762 mm), the Phoenix is a revolutionary new coating/priming system that is the most modular system available. The system can utilize one, or multiple coating and curing stations and utilizes our unique Kompac IOTech4 platform. Phoenix allows users to add outstanding finishing touches to a printed product to produce eye catching effects. Add high gloss shine, texture and grit, spot UV embellishments, scratch off spots, matte, pearlescent, soft touch feeling, spot not, areas, three-dimensional effects, and more. Capable of 250 feet (76m) per minute, the Phoenix relieves stress on low stock paper, giving power and product back to the owners.

Phoenix is great for paper handling and is designed for users looking to produce higher volumes. The Phoenix can be placed in-line with large format printers to create an automated workflow solution. Using the Kompac conveyor system, printed sheets are automatically sent to the Phoenix, where they are flood coated, cured and re-stacked. Paired with Phoenix are a sophisticated feeder and stacker allowing for full modularity of the machine. The most revolutionary aspect of the Phoenix is its integration with the IOTech4 platform which increases overall efficiency of jobs allowing quicker job turn around and can even allow users to remotely operate and monitor jobs as they go.

When it comes to providing quality solutions for our clients, Kompac goes above and beyond to meet your coating needs and deliver a product and service that you can be proud of. To learn more about the Phoenix, or if you have any questions, please contact our sales department at sales@kompactech.com

Benefits of Kompac UV and Aqueous Coatings

Laminating is a popular finishing process that has long been used to protect printed collateral and extend its lifespan, especially in situations where it will be handled repeatedly, exposed to the elements and at risk from spills. Restaurant menus are the classic example.

Lamination, however, is not purely done for pragmatic reasons. By bonding a printed substrate between two sheets of clear plastic, the ink colors can be not only preserved, but enhanced.

But now you have a choice…UV and aqueous coatings.

Benefits of UV and Aqueous Coating

With UV and aqueous coating from Kompac, you gain access to a whole new world of textures, plus productivity and cost-saving advantages. So how do these two technologies work?

UV coatings rely on UV-compatible inks (such as HP Indigo’s ElectroInk range) for maximum impact. The chemicals used cure rapidly when exposed to UV light and create a glossy, highly reflective surface that’s particularly well-suited to enhancing the appearance of printed photographs.

UV flood coating can be used to create this effect across an entire sheet, while UV spot coating lets you focus on the vital elements of your printed collateral. Typically, this might be your customer’s logo, or the part of the packaging that calls attention to a new, improved recipe or special offer.

Aqueous coatings also offer the advantage of rapid drying (ensuring seamless flow from your printing press through finishing to dispatch and increasing your hourly throughput of finished materials).

Aqueous coating differs from UV coating in that by using water-based substances, it is more environmentally friendly. It also works best when used as a flood coating (to coat entire sheets).

Technicolor Dream Coatings

Just like laminating, UV and aqueous coatings both enhance and protect your final printed product. They let you offer additional value to your customers, and also burnish your reputation for technical proficiency. When used in consumer-facing applications, they can lead directly to increased brand awareness and sales – that is, a tangible ROI against the additional costs of the coating treatments.

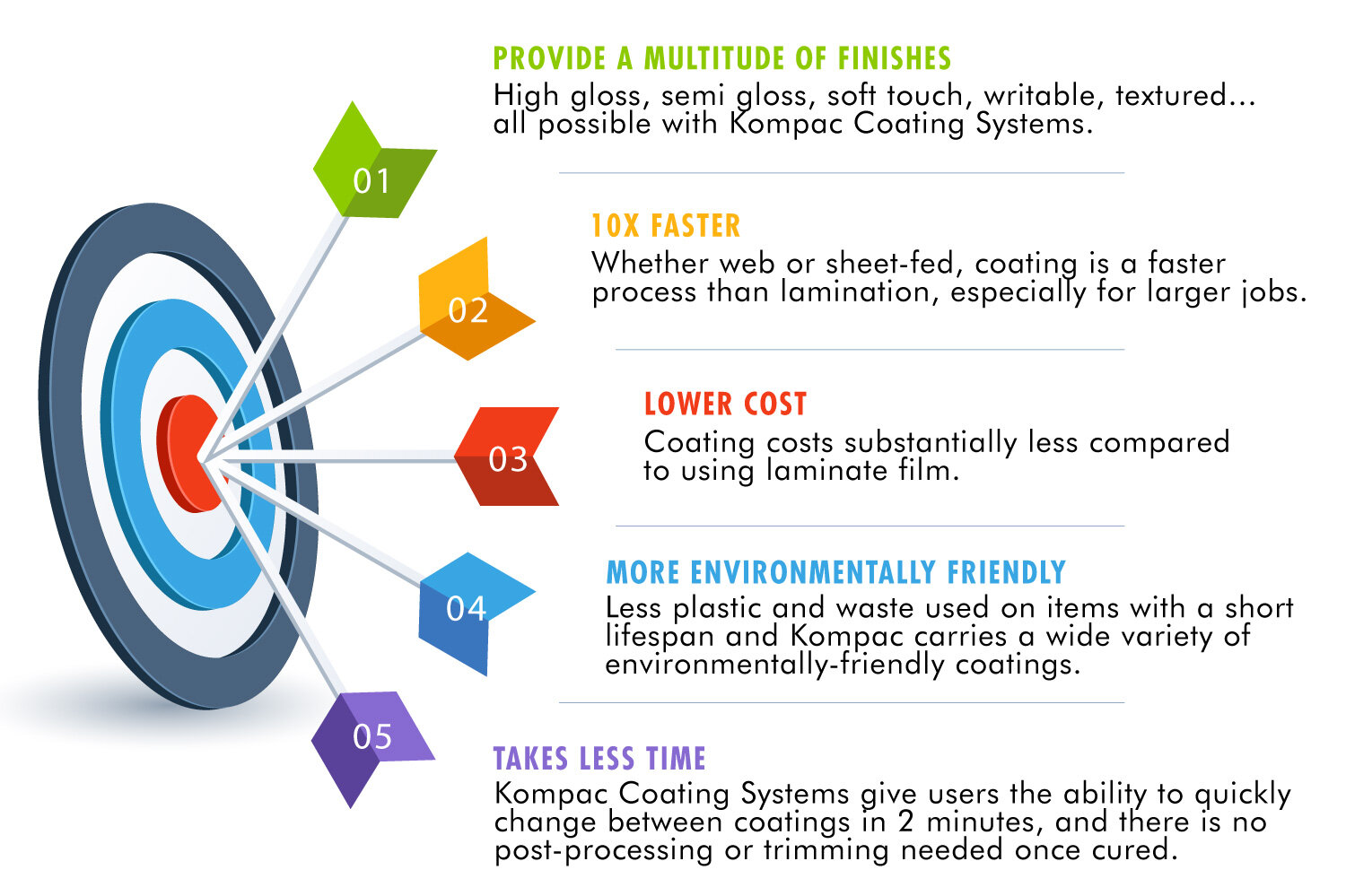

No end to the finishes you can achieve

With Kompac Coating Systems, you can create finishes for multiple applications – many of which cannot be achieved with conventional laminating. Kompac UV and aqueous coatings even include writable and glueable finishes for maximum flexibility.

They have food-safe applications, as well as offering an exceptional range of finishes designed to catch the eye and be irresistible to the touch, such as high-gloss, satin, textured and soft-touch effects.

Advantage UV and aqueous coatings

When it comes to enhanced business efficiencies, UV and aqueous coatings are very hard to beat. Both processes are up to 10x faster than conventional laminating, a factor that is particularly significant when it comes to longer runs. Coating also typically delivers lower costs than laminating, helping to maintain (or even increase) your margins in a business climate where every cent counts.

Any color as long as its green

One disadvantage of laminating is that it uses significant amounts of plastic, and because of the bonding process used, this is rarely recoverable or recyclable later on. Kompac has developed a range of lower-impact coatings, with aqueous coatings in particular offering a more sustainable alternative.

Agility is probably the most important busines attribute under existing market conditions. Being able to rapidly switch to the next job reduces unprofitable downtime, and ensures that all your presses and associated systems are running at optimum output rates. With Kompac Coating Systems, you can change between coatings in just 2 minutes – not even enough time to boil the kettle.

When it comes to providing finishing solutions to your clients, expand your offering beyond laminating with Kompac. To learn more about the exciting potential of UV and aqueous coating, check out the ONYX 30 here.

Lamination has it’s place…but UV & Aqueous Coating adds a level of value that cannot be beat!

Want more information? Send us an email!

What do YOU choose? Lamination or UV and Aqueous Coating?

Lamination has it’s place…but UV & Aqueous Coating adds a level of value that cannot be beat!

Go above and beyond and provide a full spectrum of finishes.

Watch how it’s done!

Want more information?

Send us an email!

UV Spot Coating for Print and Packaging

With Kompac Flood and Spot Coating Systems,

it's easy to enhance printed items such as business cards, labels, folding cartons, boxes and flexible packaging!

How it's done...

Priming. Flood Coating. Spot Coating. Die-Cutting. Perfing.

Kompac's ONYX 30 gives users the ability to apply Primers, UV, Aqueous, and Specialty Coatings to stock ranging from 3-30pt (60-600gsm), at speeds up to 6000 sheets per hour! Die-cut, perf and crease to produce outstanding finished products!

Kompacs ONYX 30 allows users to add outstanding finishing touches to a printed product to produce eye catching effects.

Available as an option for the ONYX 30, this semi-rotary die-cutting system provides print service centers and inplant printers the added ability to die-cut and perforate sheets quickly, and easily.

What coatings can you run with Kompac Coating and Finishing Systems?

Watch how easy it is to enhance product packaging using Soft Touch for the surface, and then spot coat using high gloss to add dimension and shine!