Kompac II Dampening System

Improve Your Press Performance

Kompac’s range of Automatic Dampening Systems can improve the performance on your press by eliminating the problems inherent in both conventional and alcohol dampening systems. The patented Kompac technology provides the operator with automatic ink/water balance. Kompac Automatic Dampeners completely re-balance themselves at each revolution and carry only the amount of ink and water demanded by the image on the plate. Kompac gives instant startup and runs trouble-free – increasing production by 30 minutes per shift.

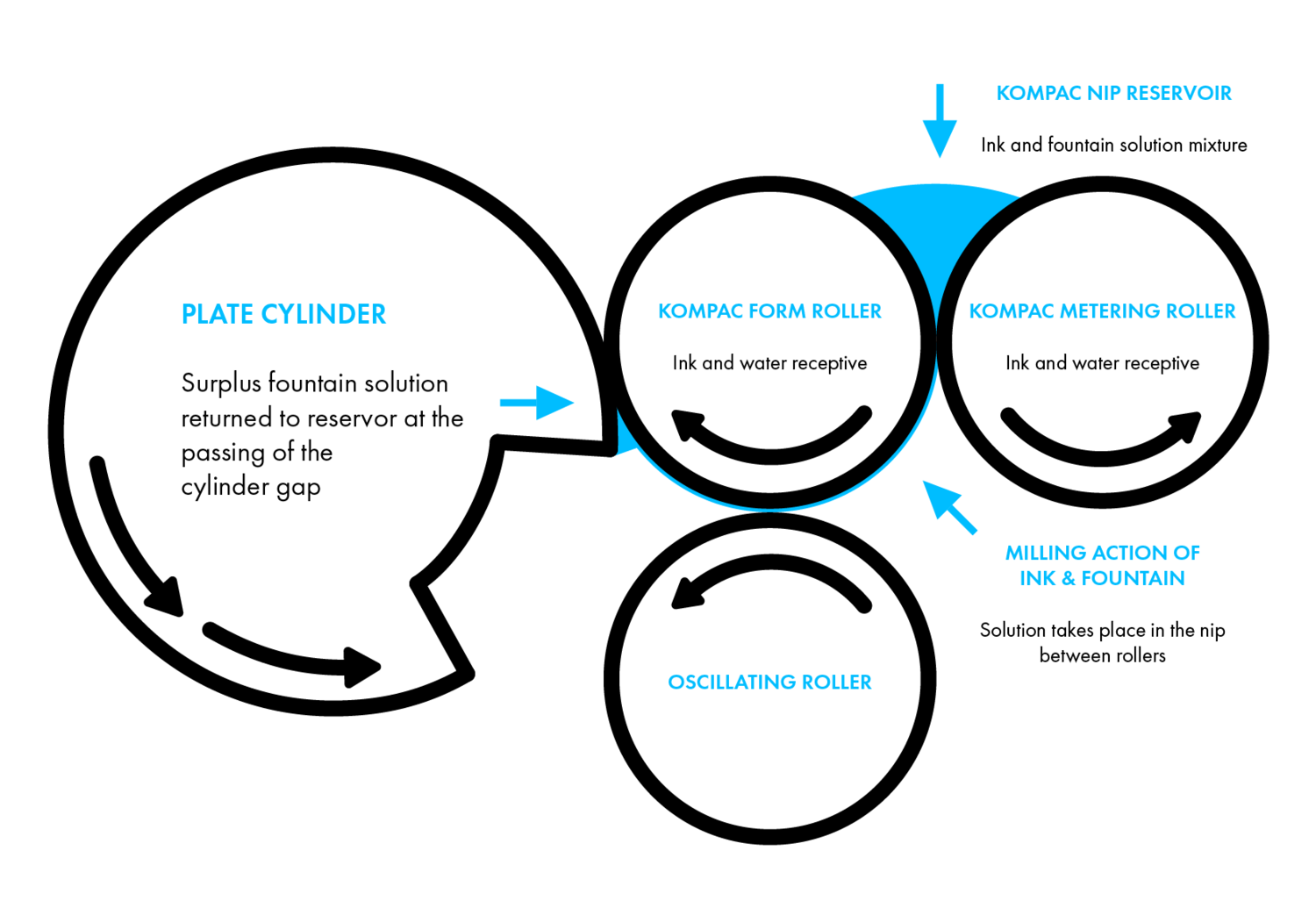

How a Kompac System Operates

Fountain solution is held in the nip reservoir between the Kompac form roller and the Kompac metering roller. The form roller rolls across the plate with the non-image area of the plate taking the fountain solution and the image area of the plate splitting a layer of ink with the form roller. The Kompac form roller is both water and ink receptive. Ink and fountain solution are milled under pressure at the roller nip. The oscillator roller smoothes out the ink and water film for improved Kompac performance.

Kompac Systems Pays for Itself in 6 Months or Less

Between a 50% reduction in stock waste and an average increase in production of 30 minutes per shift, the Kompac Automatic Dampening System typically pays for itself in less than 6 months. The Kompac Dampening System prints a thinner film of ink and water enabling jobs to be turned over faster and permitting larger solids, complicated screens, tiny reverses and difficult jobs to be run in an efficient manner. The Kompac Dampening system is a "press proven" technology with over 100,000 installations worldwide.

AB Dick

350, 350CD, 360, 360CD, 360QP, 360QPC, 360PRO, 8805,8810

(with Plastic Safety Cover) Parts Catalog - AB5060

8805, 8810, 8815, 8820 (with Metal Safety Cover) Parts Catalog -AB 8800

8915, 8920 Parts Catalog - AB 8900

375, 375CD, 375QP, 375QPC, 375PRO, 9805, 9810, 9810XC, 9810XCS, 9815, 9820, 9835, 9840, 9850 (with Plastic Safety Cover) Parts Catalog - AB 9875

9805, 9810, 9810XC, 9810XCS, 9815, 9820, 9835, 9840, 9850, 9870 (with Metal Safety Cover) Parts Catalog - AB 9800

9910, 9910XCS, 9910XC2, 9970 Parts Catalog - AB 9900

385, 385CD, 385PRO, MG2-22 Parts Catalog - AB 3850

9880, 9880D, 9890, 9890D Parts Catalog - AB 8090

9985 (Two Unit Kit) Parts Catalog - RYB332

4995, 4995A, 9995, 9995A (Single Unit Kit with RRM) Parts Catalog - RYB334R

4995, 4995A, 9995, 9995A (Single Unit Kit with Bottle) Parts Catalog - RYB334R

Kompac II Dampening System

AB Dick | ATF Chief | Gestetner | Hamada | Itek | Multigraphic | Ryobi | Toko

ATF Chief

ATF 15, 115, 215 (Check press serial number) Parts Catalog - AF 15/AF 15G

ATF 15, 115, 215 (Check press serial number) Parts Catalog - AF 17/AF 17G

Hamada

RS 34-M, RS 34L-M, VS 34-M, VS 34L-M (Main Head) Product Catalog - HMD34-1-O

RS 34 II-M, RS 34LII-M, VS 34 II-M , VS 34LII-M (Main Head) Product Catalog - HMD34-1-N

RS 34S-M, RS 34LS-M, VS 34S-M, VS 34LS-M (Second Color Head) Product Catalog - HMD34-2-O

RS 34II S-M, RS 34II L-M, VS 34II S-M , VS 34II L-M (Second Color Head) Product Catalog - HMD34-2-N

H234, H234CX (with Bottle) Product Catalog - HMD234

H234, H234CX (with RRM) Product Catalog - HMD234R

H234-A (with RRM) Product Catalog - HMD234A-R

H234-A (with Bottle) Product Catalog - HMD234A

C48EX, C48CX, C48EX-CF, C48CX-SF (Single Unit Kit) Product Catalog - HMD48

C248E, C248EX, C249CX, C248E-SF, C248EX-SF, C248CX-SF, H248E, H248EX, H248CX, H248E-SF, H248EX-SF, H248CX-SF (Two Unit Kit) - Product Catalog Part 1 HMD248 & Part 2 HMD248R

C252E, C252CX, C252E-SF, C252CX-SF (Two Unit Kit) Product Catalog Part 1 HMD252 & Part 2 HMD252R

700CD, 770CD, 700CDX, 775CDX, E47, E47S E47-NP (Main Head) Product Catalog - HMD47-1-O

775CDA, E47S, E47S-NP (Second Color Head) Product Catalog -

HMD47-2-ODU34-M (Upper Head) Product Catalog - HMD34-1-O

DU34II-M (Upper Head) Product Catalog - HMD34-1-N

DU34-M (Lower Head) Product Catalog -

DU34 II-M (Lower Head) Product Catalog - HMD-DU34-2-N

500CDA, 550CDA, 555CDA, 600CD, 660CD, 665CD (Main Head) Product Catalog - HMD600-1

550CDA, 660CDA (Second CoItek 975 Product Catalog - HMD600-2-O

555CDA, 665CD (Second Color Head) Product Catalog - HMD600-2-N

611ECD, 611EXL, 612ECD, 612EXL, 661ECD, 661EXL, 662ECD, 662EXL (Main Head - DISCONTINUED) - Parts Catalog - HMD6112

Gestetner

GST11 Parts Catalog - GST11

GST12 Parts Catalog - GST12

GST13 Parts Catalog - GST13

Itek

Itek 950, 960 Product Catalog - RYB2728

Itek 975 Product Catalog - RYB3200

Itek 985 Product Catalog - RYB32MCD-KM

Itek 3985 Two Unit Kit Product Catalog - RYB332-KM

Itek 3980, 3980TC, 3980NPI, 3980TCNPI Product Catalog -RYB33-KM

Multigraphic

1250, 1250CD, 125C, 1250SG, 1250N, 1250OR, 1250G, 1250W, 1250LW Product Catalog - M125

1250, 1250CD, 125C, 1250SG, 1250N, 1250OR, 1250G, 1250W, 1250LW (Improved Plate Clearance) Product Catalog - M125IPC

1250, 1250CD (Multi Lever Presses) Product Catalog -

M125ML2650, 2650W, 2650N, 2675, 2850, 2850E, 2850N, 2875, 2975, 2975E (Systems 4,5,6 & 7) Product Catalog - M2629

1330, 1360, 1450, 1650, 1650XE, 1650MC, 1650GPC Product Catalog - M1316

1330, 1360, 1450, 1650, 1650XE, 1650MC, 1650GPC (Improved Plate Clearance) Product Catalog - M1316IPC

1850, 1850CD, 1870, 1870CD, 1860, 1860XE, 1860GPC, 1860MC, 1960XE, 1960MC, 4610, 4620 (Main Head) Product Catalog - M1819-I-KM

1850, 1850CD, 1870, 1870CD, 1860, 1860XE, 1860GPC, 1860MC, 1960XE, 1960MC, 4610, 4620 (Second Color Head) Product Catalog - M1819-II-KM

1218 (Serial number 987282 and below) Toko 1800, 4700, 4750 (with Plastic Safety Covers) Product Catalog - TK47

1218 (Serial number 987282 and above) Toko 1800, 4700, 4750 (with Metal Safety Covers) Product Catalog - TK4750M

Toko

1800, 4700, 4750 (with Plastic Safety Covers) Product Catalog - TK47

1800, 4700, 4750 (with Metal Safety Covers) Product Catalog - TK4750M

Ryobi

2700, 2700CD, 2800, 2800CD, 2800XL Product Catalog - RYB2728

3200, 3200CD, 3200XL, 3200NP Product Catalog -

RYB32003200CD (with Wider Image Area) Product Catalog - RYB3200W

3200MCD Product Catalog - RYB32MCD-KM

3302H, 3302HA, 3304H, 3304HA (Single Unit Kit with RRM) Product Catalog - RYB334R

3302H, 3302HA, 3304H, 3304HA (Single Unit Kit with Bottle) Product Catalog - RYB334

3302M (Two Unit Kit) Product Catalog - RYB332-KM

3300MR, 3300CR Main Head Product Catalog -

RYB33-KM512, 512NP (Main Head) Product Catalog - RYB5102-1

512, 512NP (Second Color Head) Product Catalog - RYB5102-2

520. 520NP Product Catalog - RYB52

522, 522NP (Two Unit Kit with Bottle) Product Catalog - RYB522

522, 522NP (Two Unit Kit with RRM) Product Catalog -