Onyx 30i

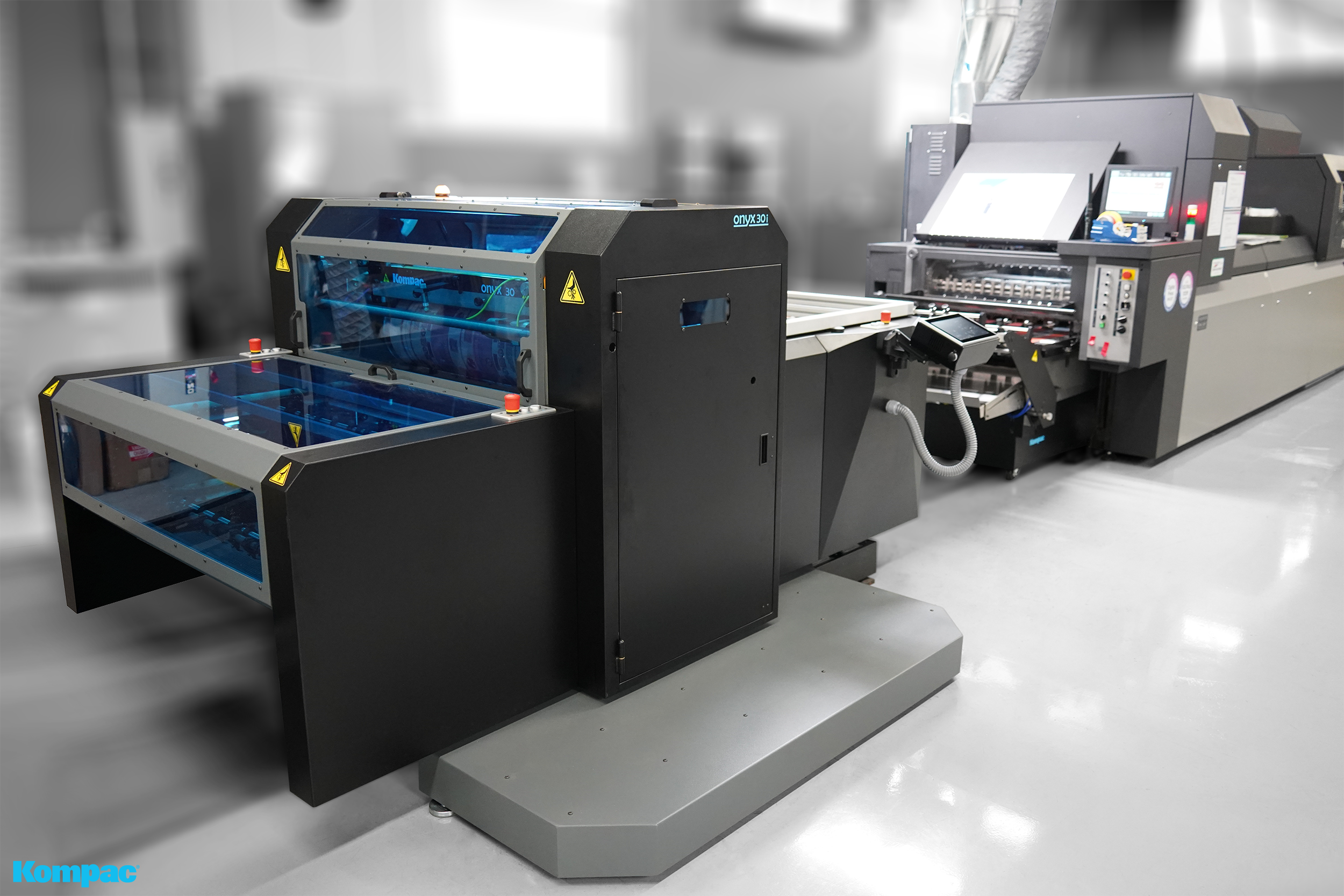

The all new Kompac Onyx 30i in-line flood/spot coating system provides a quick and easy way to apply UV/AQ coatings and specialty coatings to a wide variety of substrates, in one single pass on B2 or smaller sized sheets, from text weight to card stock thicknesses. The Onyx 30i is the perfect solution for medium to large run digital jobs and also perfect for commercial packaging where glue tabs and spot not coated areas are required for boxes, pocket folders and mailers.

Onyx 30

Enhance your print and packaging with UV/Aqueous flood and spot coating embellishments. Onyx 30 allows users to add outstanding finishing touches to a printed product to produce eye catching effects. Add high gloss shine, texture and grit, spot UV embellishments, scratch off spots, matte, pearlescent, soft touch feeling, spot not, areas, three-dimensional effects, and more!

Die Cutting on the Onyx 30

Available as optional equipment for Kompac’s UV/Aqueous ONYX 30, the semi-rotary die-cutting system provides the added ability to die-cut and perforate sheets quickly, and easily.

The magnetic die system is easy to attach, giving print service providers the flexibility to not only prime and coat printed materials – but also cut, perforate and crease sheets to produce everything from product packaging, to business cards, folders, greeting cards, direct mailers, and more!

Available Options

Optional: Die-Cutting, Perfing, or Creasing

Optional: IR Dryer (or Duplex IR Dryers)

Patented: Short-wave intensity bulbs with Air Curtain

Kompac Vac: For quick & effortless 2-minute coating change & clean up

Coating Sensor: Automatically detects coating level & replenishes

IR Dryer: Dries aqueous coatings and assists UV coating wet-out for increased gloss

Sheet Detection: Monitors to help prevent fires and track sheet counts

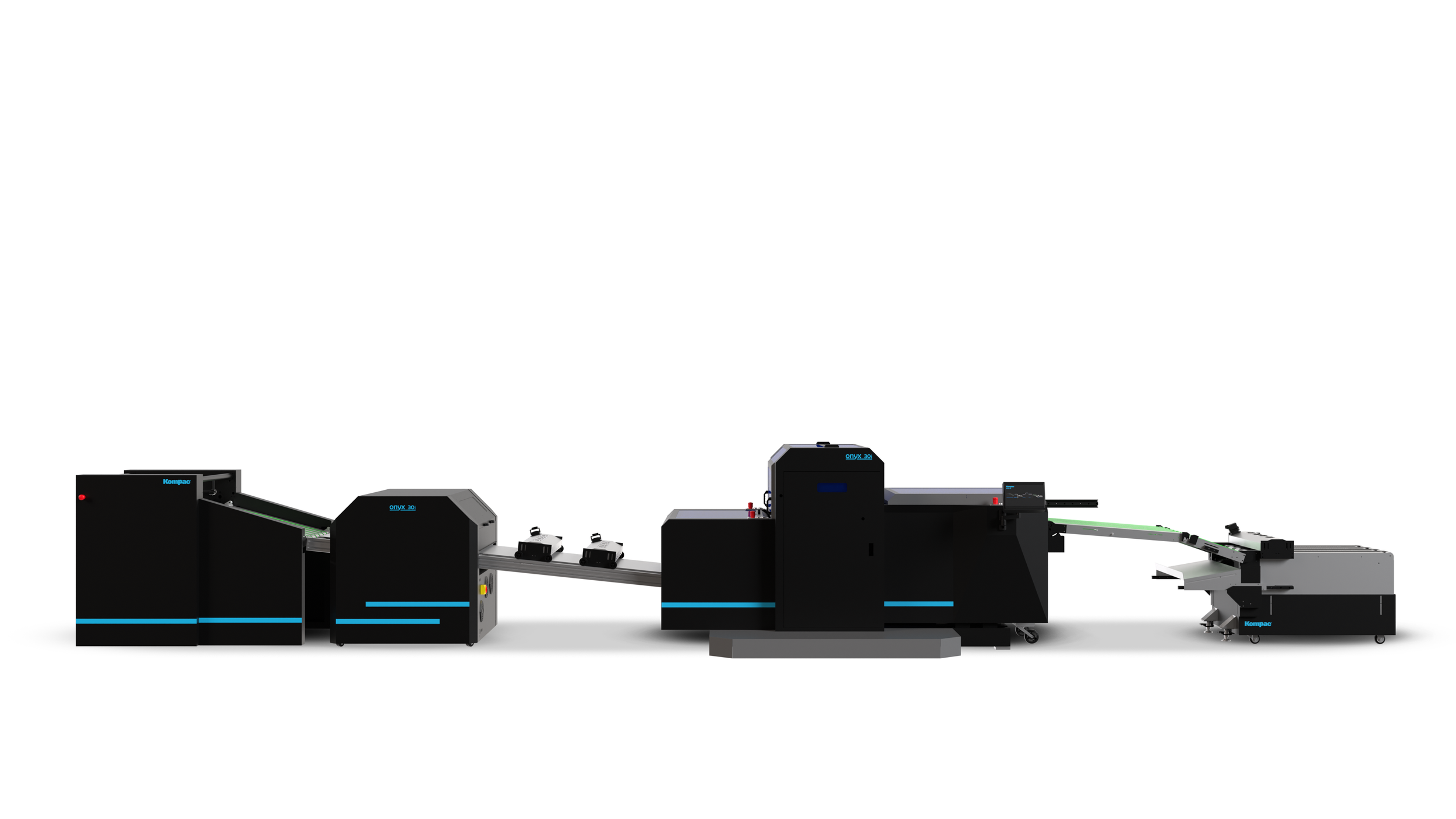

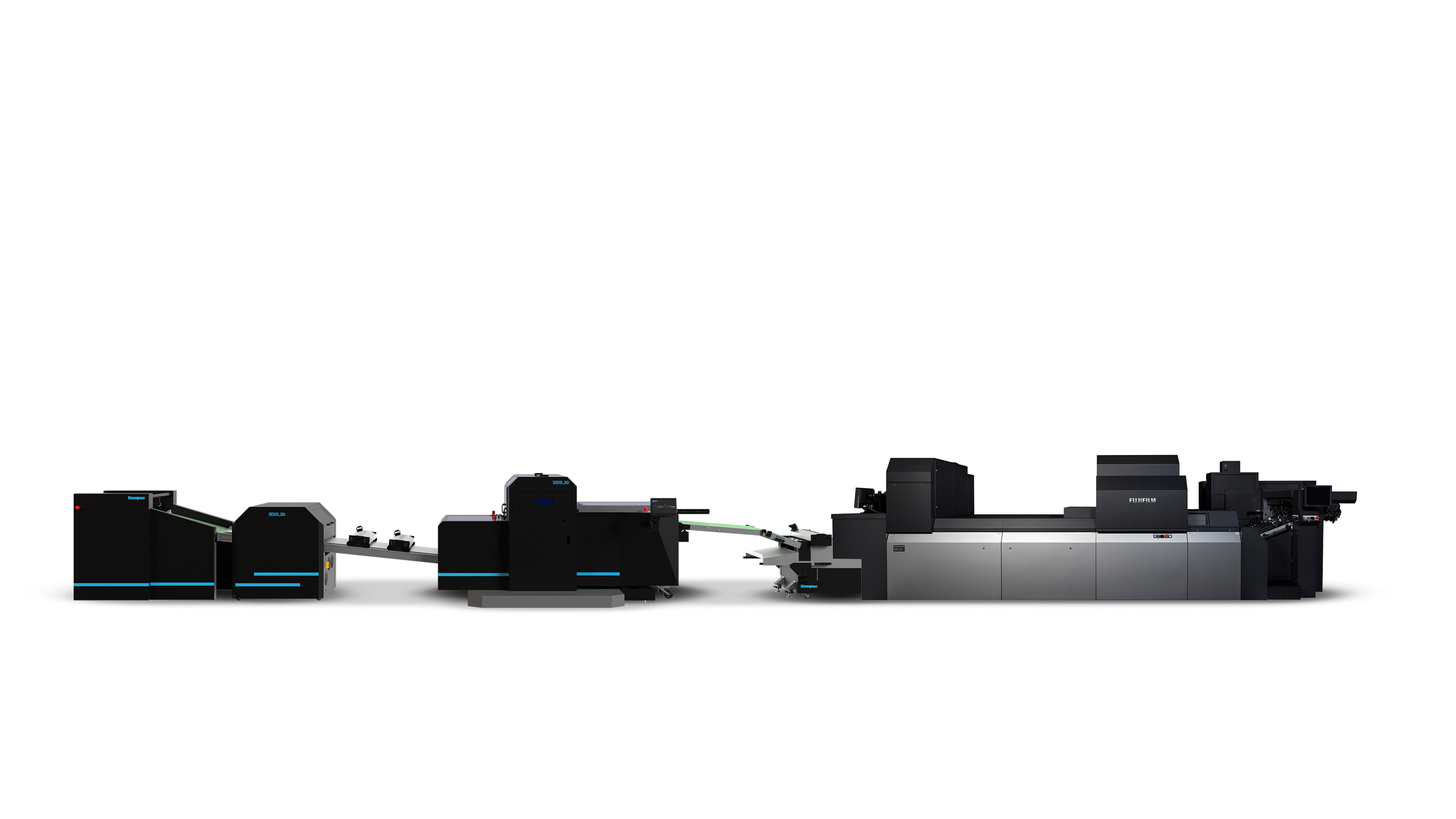

Interface Conveyor: Allows for inline coating on select digital & offset presses

Korona Treating: For plastic, synthetic, and metalized substrates

IOTech4: Communication system for better efficiency and metrics

Paper Handling

In-Line Sheet Fed: For users looking to produce higher volumes, the Onyx can be placed in-line with large format printers to create an automated workflow solution. Using the Kompac conveyor system, printed sheets are automatically sent to the Onyx, where they are flood coated, cured and re-stacked.

Specifications

Flood & Spot Coat

Easily apply UV, Aqueous, Specialty Coatings and Primers

Optional Chambered Anilox Coating System for Soft Touch and UV Matte (in addition to standard Kompac Coating System)

Handles substrates up to 22” x 31.5” (560mm x 800mm), 22” x 30” (560 x 762mm) in Anilox Mode

Coat/Prime at up to 6000 sheets per hour

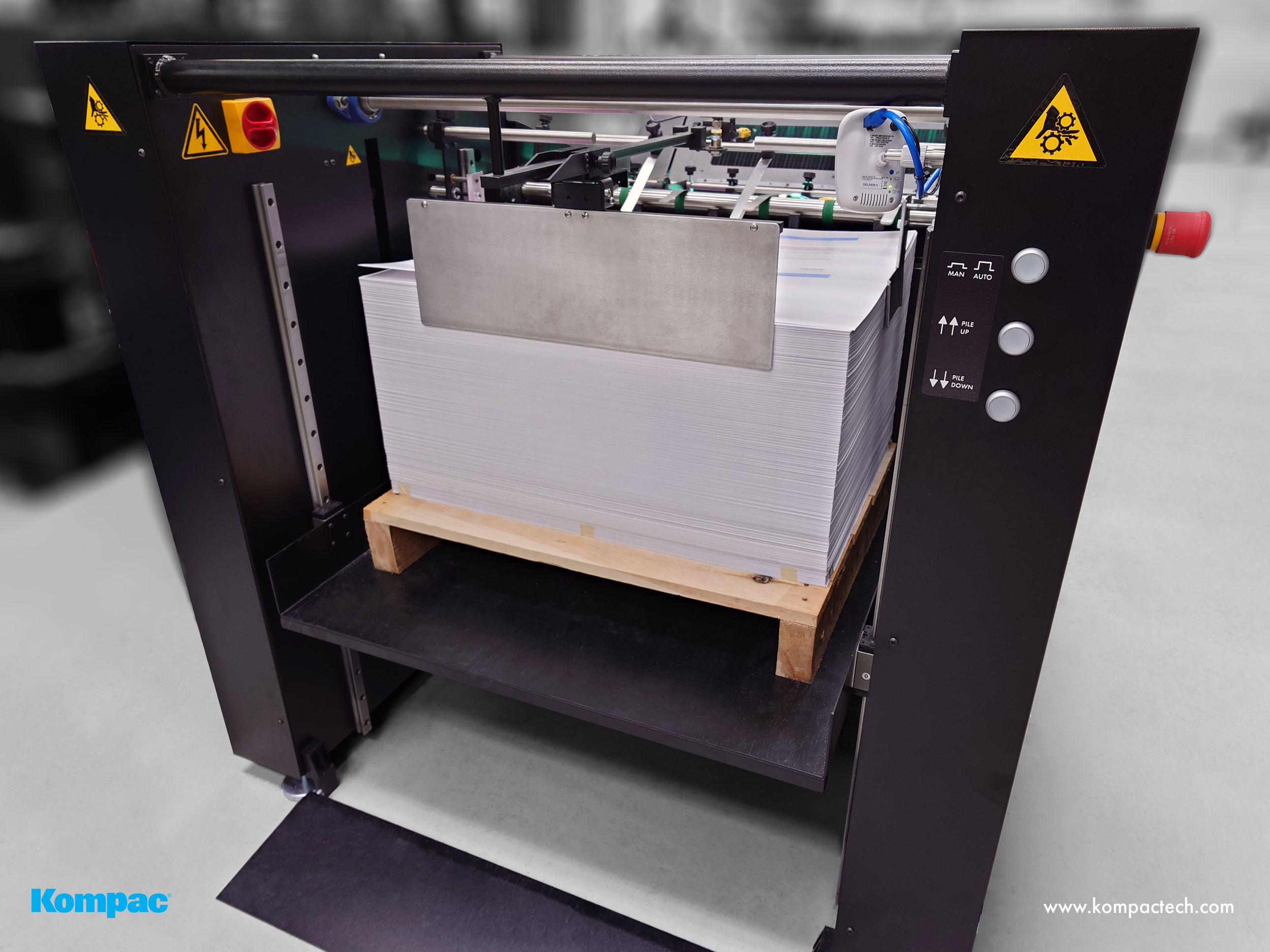

System includes the Kompac High Pile Pallet/Dolly Stacker, handles 34”(86cm) lift

Automatic Stream Feeder accepts pallets/dollies right from your digital or offset press (No “hand” loading means it is the perfect solution for variable data or sequential jobs)