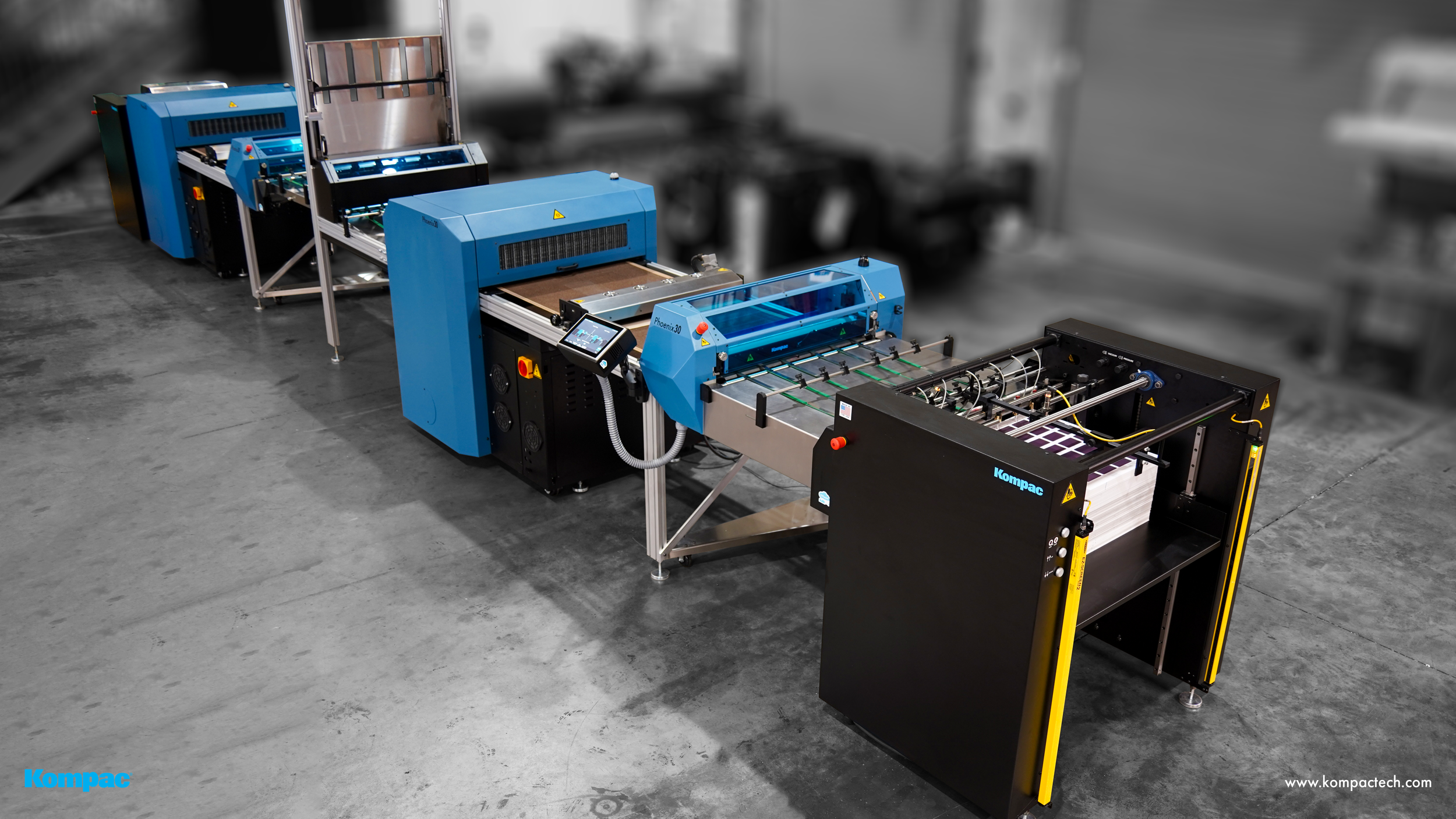

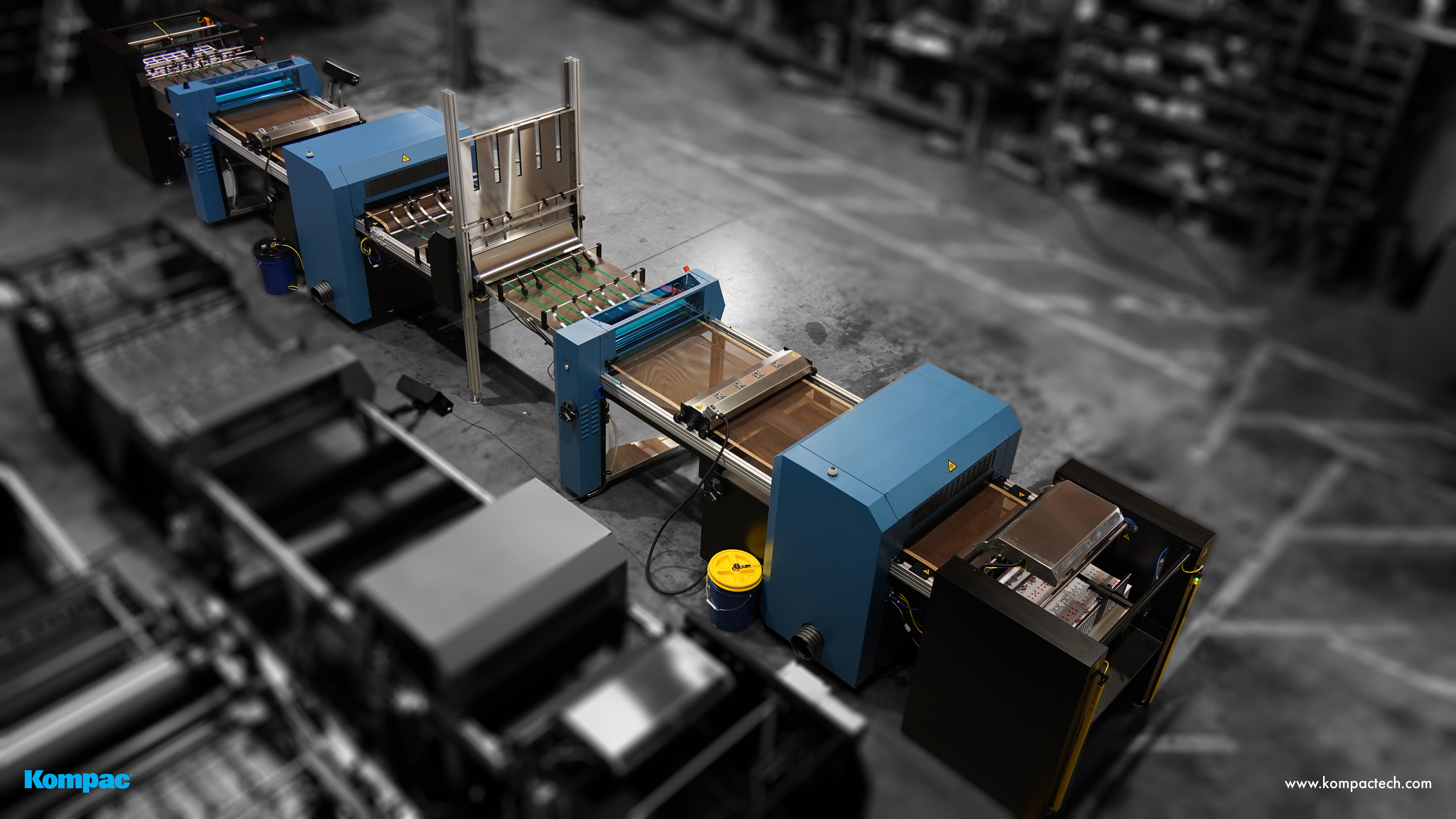

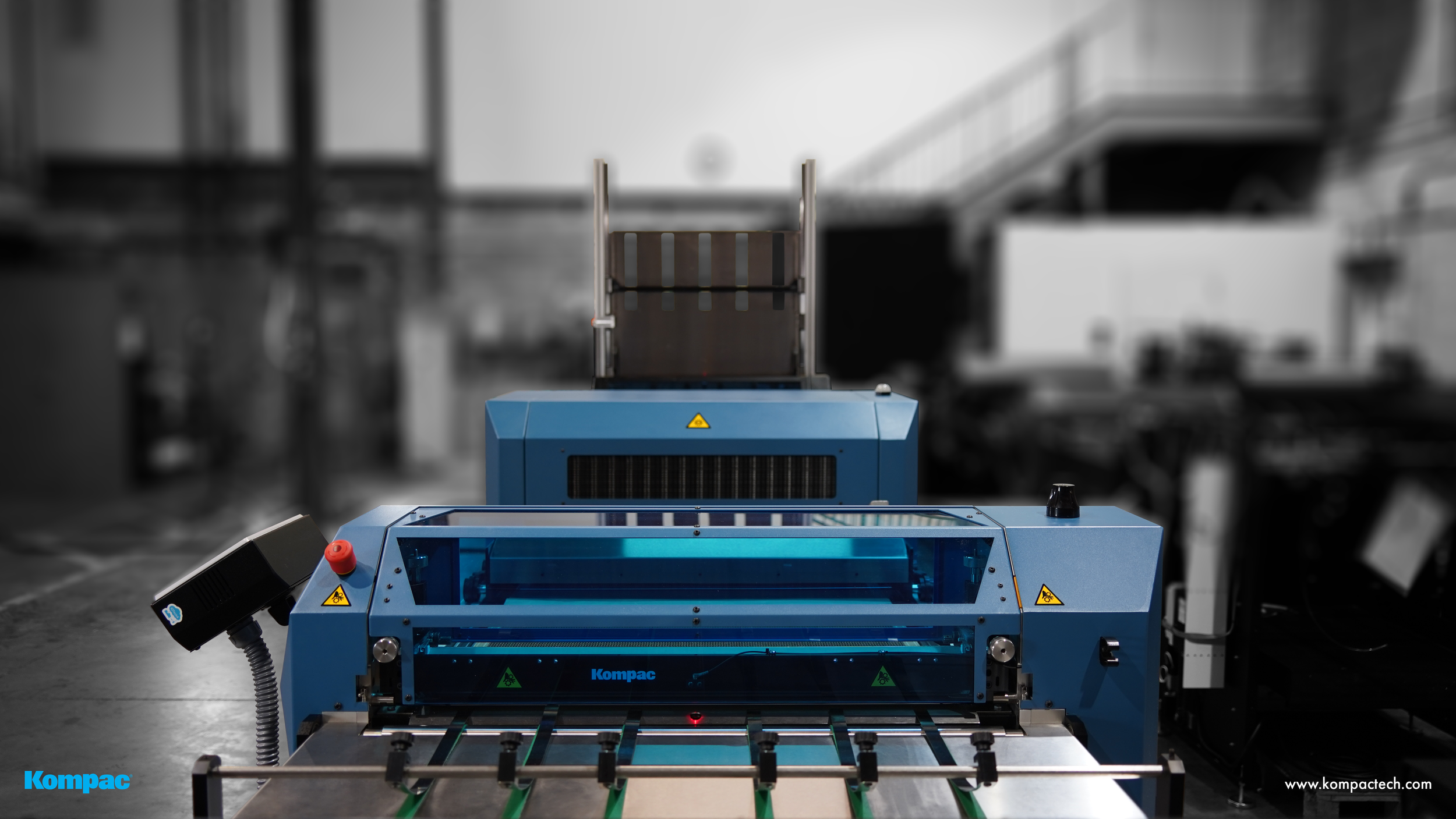

The Phoenix Duplex is Kompac’s next generation flood coating and priming system, with sheet turning capability for two-sided applications. Configured inline or nearline, the system is designed as a coater, sheet turner, and a second coater, ideal for duplexing in a single pass. With flexibility in mind, the Phoenix Duplex is designed so that different finishes can be applied to each side. The system can be configured to apply multiple primers/coatings per side in a single pass.

Phoenix Duplex

Kompac’s next generation coating and priming system, with sheet turning capability for two-sided applications. Configured inline or nearline, the system is designed as a coater, sheet turner, and a second coater, ideal for duplexing in a single pass. With flexibility in mind, the Phoenix Duplex is designed so that different finishes can be applied to each side. Further, multiple coating heads can be added to one or both coaters, in order to apply multiple primers/coatings per side in a single pass.

Running Multiples Finishes?

Available Options

Kompac Vac: For quick & effortless 2-minute coating change & clean up

Coating Sensor: Automatically detects coating level & replenishes

IR Dryer: Dries aqueous coatings and assists UV coating wet-out for increased gloss

Sheet Detection: Monitors to help prevent fires and track sheet counts

Interface Conveyor: Allows for inline coating on select digital & offset presses

High Pile Feeder & Stacker: Pallet/Dolly loadable feeder & stacker for high volumes

Korona Treating: For plastic, synthetic, and metalized substrates

IOTech4: Communication system for better efficiency and metrics

Paper Handling

In-Line Sheet Fed: For users looking to produce higher volumes, the Phoenix can be placed in-line with large format printers to create an automated workflow solution. Using the Kompac conveyor system, printed sheets are automatically sent to the Phoenix, where they are flood coated, cured and re-stacked.

Feeders & Stackers: For increased speed over hand-feeding, the Phoenix is modular, and can be paired with our feeders and stackers.

Specifications

20” & 30” sheet width by virtually unlimited length.

UV & IR drying available. Can be configured pre or post coating with up to 4 IR units.

Multiple coating systems. Up to 4 coating units per system anilox or standard.

Variable length conveying pre or post curing for coating wet out or additional curing time.

High speed. Capable of 250 feet (76m) per minute.

Featuring Kompac IOTech4 network platform for increase efficiency and job turn around.

Made in the USA.