What do YOU choose? Lamination or UV and Aqueous Coating?

Watch how easy it is to enhance product packaging using Soft Touch for the surface, and then spot coat using high gloss to add dimension and shine! Spot coat...

NEW EZ Koat 2040 and 3040 Feeder and Stacker for 40" Sheets!

The EZ 2040/3040 Feeder & Stacker are production-level equipment that allows greater throughput on the Kompac EZ Koat 20 and 30 UV & aqueous coating systems. This coating machinery can now fit an incredible 20”x40” (50.8cm x 101.6cm) sheet with no loss in speed. It also accepts pallets (32” lift) to avoid hand-loading of sheets, and make the pre- and post press finishing a breeze!

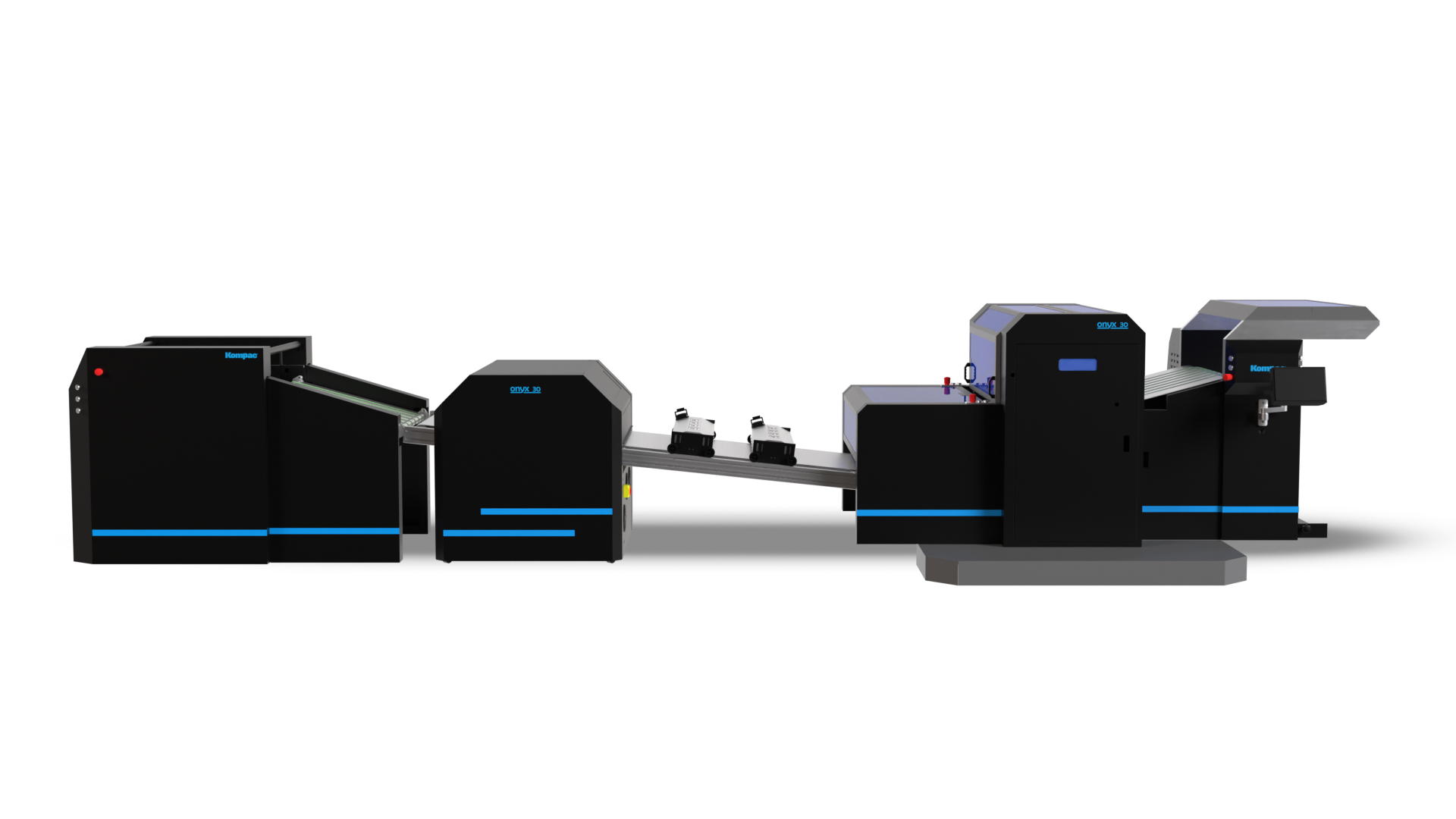

NEW Onyx 30 UV/AQ Coating System

Kompac has announced the release of the ONYX 30, a high production priming and coating system for the application of UV, Aqueous, Primer/Sapphire, and specialty coatings to a wide variety of substrates. The nearline finishing unit provides commercial printers and in-plant facilities a flexible, cost-effective way to prime, flood, and spot coat sheets up to 22” x 32” (560mm x 800mm) wide at speeds up to 6000 sheets per hour. The first install of the ONYX 30 took place in August with a US-based prepress & print shop with multiple HP Indigo Digital Presses in operation.

Kompac to Highlight Anilox and Soft Touch Coating at Xeikon Cafe

During the event, Xeikon owners and those considering acquiring a Xeikon press, will be able to speak to team members from Kompac and find out about how the digital printers and UV/aqueous coating technology can be paired to create more efficient workflows and provide new opportunities for everyone from inplant printers to label and packaging converters alike.

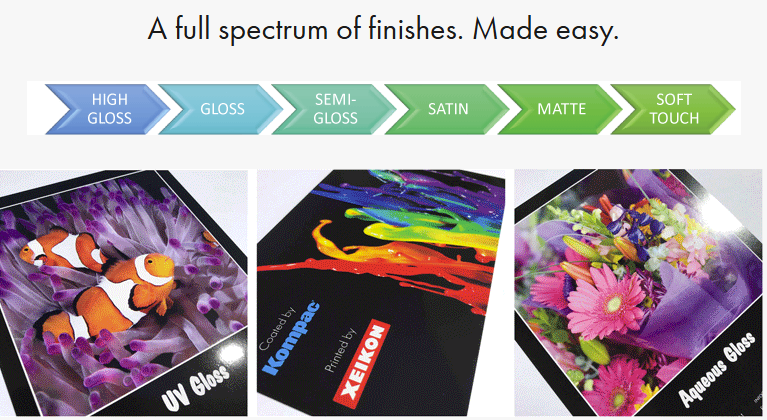

NEW FROM KOMPAC: Chambered Anilox for Soft Touch & Matte Coatings

Users can now easily run a full spectrum of coatings including: high gloss, gloss, semi gloss, satin, matte, soft touch and more - all on one machine! The NEW Kompac Chambered Anilox Roller System makes it easy to run more difficult-to-run coatings like matte and soft touch. Changeover between systems takes minutes!

Kompac Demonstrates High Gloss UV Flood Coating at Dscoop Dallas

Team members from Kompac demonstrate high gloss UV flood coating of 20” cut sheets at HP’s Dscoop Event that took place in Dallas, TX.

Kompac To Show EZ Koat 20 Plus at the Xeikon Cafe!

Xeikon Café North America is a learning event offered by Xeikon and its Aura partners, offering the opportunity to understand, evaluate and experience digital production. It provides the tools for commercial & in-plant printers and label & packaging converters in the U.S. and Canada to make informed business decisions. Through demonstrations, presentations, workshops and discussions, participants receive first-hand actionable information and advice on industry innovations and trends.