Kompac to attend drupa 2020 in Düsseldorf, Germany

Visit Kompac in Booth 13C03

The team from Kompac is pleased to announce they will be attending drupa 2020 in Düsseldorf, Germany.

During the show you can talk to the experts about high-speed UV/Aqueous coating systems and find the perfect solution for your in-house coating needs.

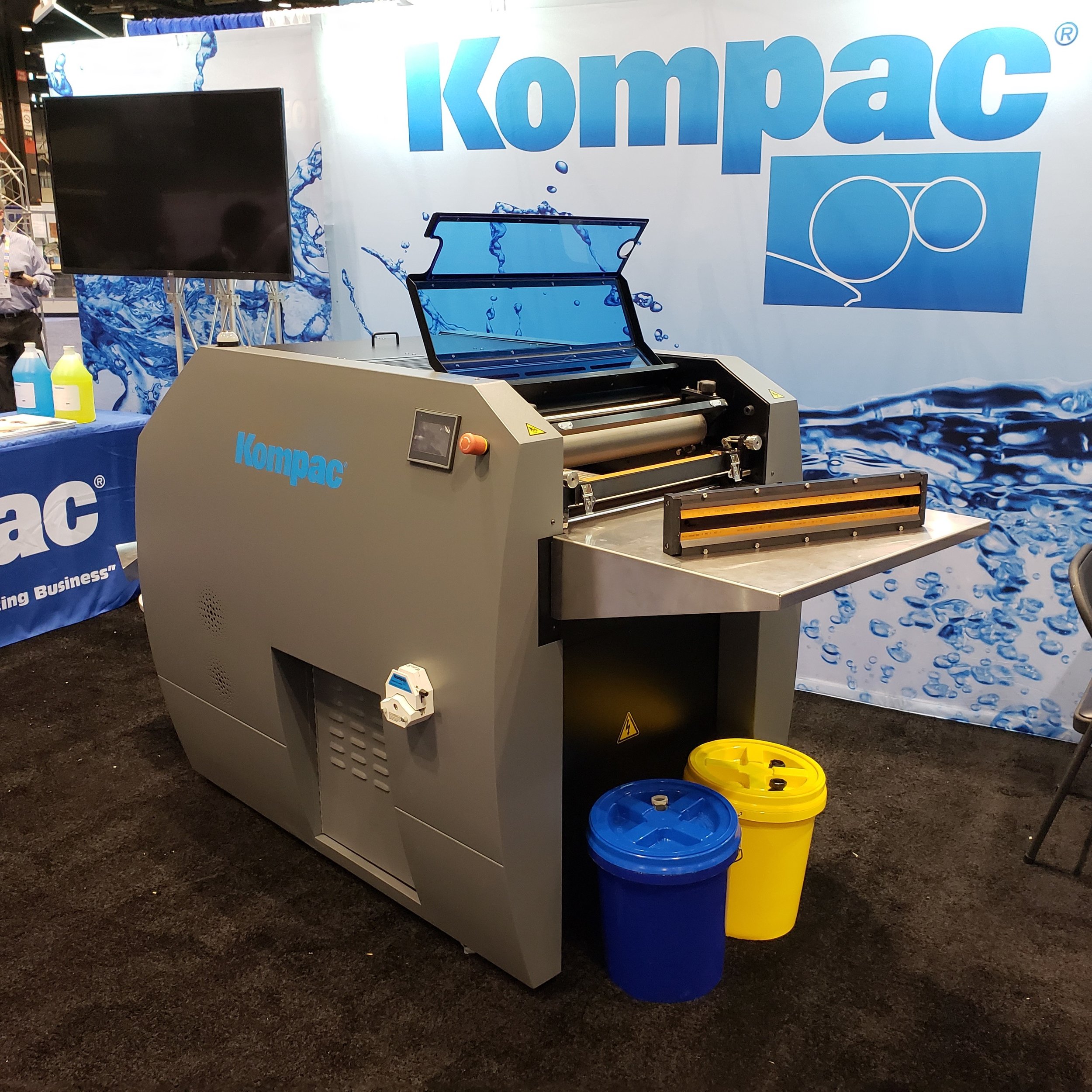

Being demonstrated at the show is the EZ Koat 20 Plus with chambered anilox, for running Soft Touch and matte coating. This 20” coating system can be configured for both sheets and web, inline and offline.

Team members from Kompac demonstrate high gloss UV flood coating of 20" cut sheets that were printed on the HP Indigo 12000 and finished on the EZ Koat 20 Plus

Book a meeting with the team from Kompac

What kind of coatings can you apply with an EZ Koat?

For more information on Kompac products or to set up a meeting time, please fill out the form and a member of our sales team will be in contact soon.

We look forward to seeing you soon!

About drupa

drupa provides crucial impulses for print, media, packaging production, and industrial applications – especially in the vertical markets as well. The world’s leading trade fair for printing technologies offers outstanding networking opportunities and potential for excellent business dealings. This is where innovations are brought into the market, new business models are developed, and new partnerships are formed.

drupa is an international magnet for visitor target groups from a wide variety of industries. In addition to the printing and packaging industry, there are also groups from vertical markets such as consumer goods, luxury goods, cosmetics, bank and safety technology, and many more. More than half of its visitors come to drupa with specific investment projects.

Kompac Celebrates 40 Years in Business!

Reflecting on the past 40 years of operation, it’s inspiring to see how the products and team have grown. Family is at the heart of Kompac, and we’re proud to have built a global network, while maintaining our roots in the United States.

To our past and current clients, thank you for keeping us in business. Because of you, Kompac has continued to gain knowledge, grow and innovate over the past 40 years. It’s because of you that we can continue to share the wealth of knowledge and experience that you helped us build.

What started as one product, has turned into a journey and we’re confident that we will continue to produce high-quality products with the Kompac name for many years to come.

Thanks again,

Thomas Hayes, President of Kompac

NEW Onyx 30 UV/AQ Coating System

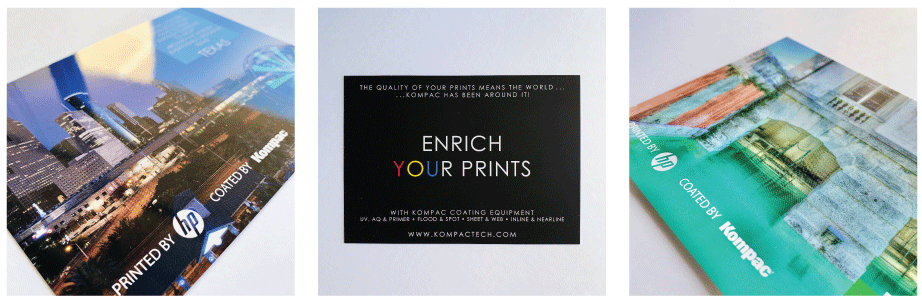

ENRICH YOUR PRINTS

with the ONYX 30 UV/AQ Spot Coating & Priming System

Kompac has announced the release of the ONYX 30, a high production priming and coating system for the application of UV, Aqueous, Primer/Sapphire, and specialty coatings to a wide variety of substrates. The nearline finishing unit provides commercial printers and in-plant facilities a flexible, cost-effective way to prime, flood, and spot coat sheets up to 22” x 32” (560mm x 800mm) wide at speeds up to 6000 sheets per hour. The first install of the ONYX 30 took place in August with a US-based prepress & print shop with multiple HP Indigo Digital Presses in operation.

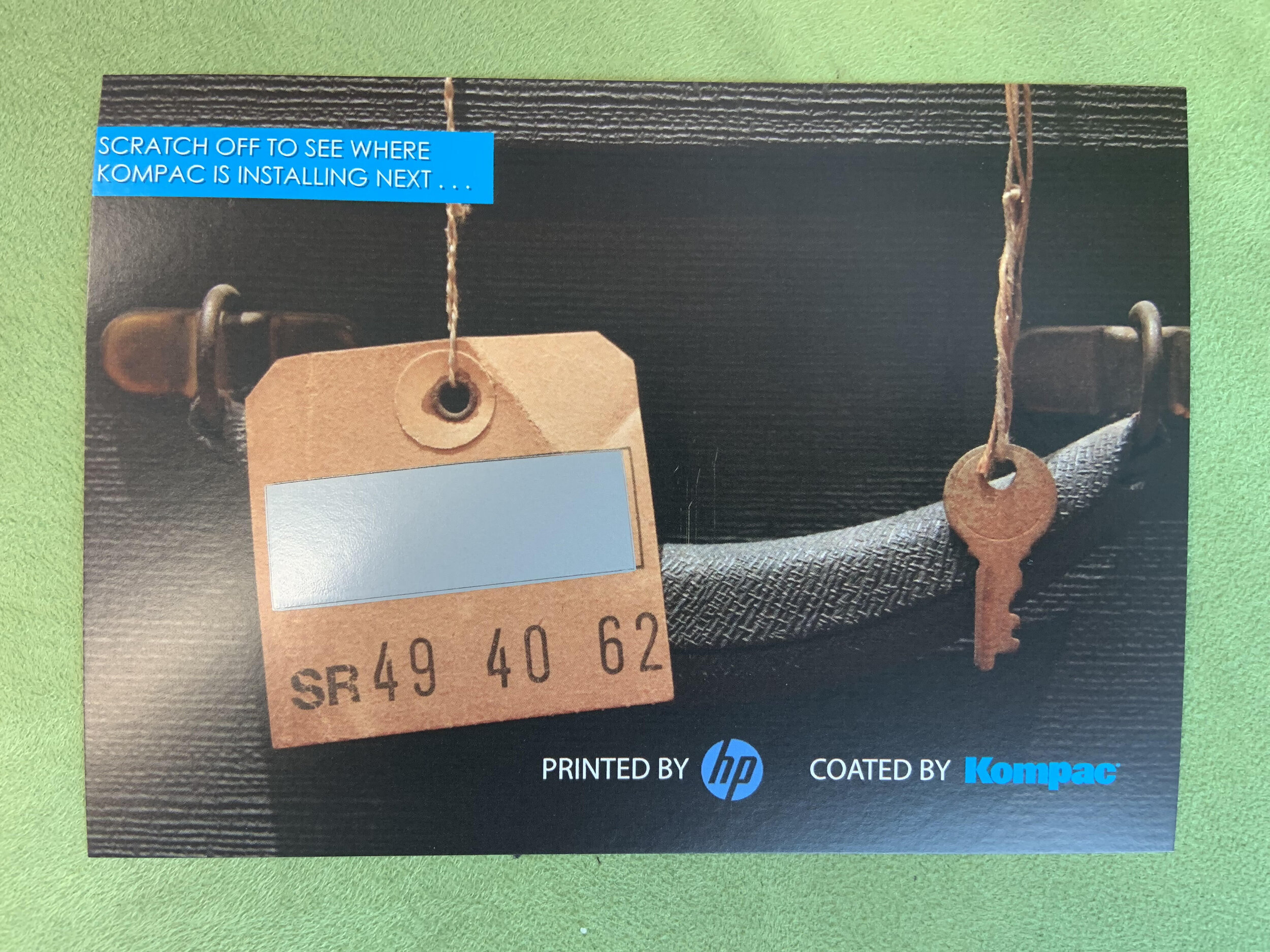

Compatible with most large offset and digital presses, the ONYX 30’s coating capabilities make it easy to not only flood coat to protect the printed surface of the substrate, but enhance the quality of printed output with spot coating embellishments such as textured, scratch-off, Soft Touch, satin, and more.

Kompac’s patented Vac Cleaning System allows users to change between coatings with ease. It greatly reduces changeover time, allowing operators to clean the equipment and switch coatings in less than 2 minutes. As a result, users can go from running UV gloss for flood coating, and switch over to the optional chambered anilox system to run aqueous soft-touch coating in just moments.

Pictured: Scratch off coating on print samples

Designed to fit the needs of a variety of production environments, the ONYX 30 coating system includes an Automatic Stream Feeder, which provides high throughput and accurate registration of every sheet for spot and spot-not coating. It handles a wide variety of stock weights and substrates ranging from 3pt to 30pt (60 to 600g/m2), and lateral pallet movement allows the coating system to accept pallets and dollies directly from the digital or offset press. Also included is the Komapc Stacker, which automatically descends and jobs, creating the perfect stack every time – allowing for quicker turnaround for bindery and further finishing.

Available Options & Specifications

The ONYX 30’s modular design allows it to be configured with optional equipment to increase production and overall capabilities. These include:

Chambered Anilox Coating System - Makes it easy to apply Soft Touch and UV Matte coating

Die-Cutting, Perfing, or Creasing – This magnetic die system increases versatility for pre and post-press finishing processes and increases short run capabilities when not spot coating

IR Dryer (or Duplex IR Dryers) - Quickly dries aqueous coatings and primers with short wave, high-intensity bulbs and instant on/off capability. Hot air knives aide in the removal of moisture and decrease drying times.

REQUEST INFO

Kompac Releases New Coating & Priming System

Introducing the NEW Onyx 30

UV/AQ Spot Coating & Priming System

The ONYX 30 is an exciting nearline coating, priming, and die cutting system, providing a quick and easy way to apply UV, Aqueous, Primer/Sapphire, and specialty coatings to a wide variety of substrates.

From ultra thin paper to plastics, card stock and lenticular; whether digital output or offset, each job will have the visual appeal, lasting durabiilty, protection and rub-resistant finish that your customers expect. Flood or Spot coat, the Kompac Onyx 30 is the most flexible, cost-effective coating system on the market today!

Available Options & Specifications

Flood & Spot Coat

Easily apply UV, Aqueous, Specialty Coatings and Primers

Perfect solution for medium/large Digital Printers, Commercial Packaging, and Label Printers

Optional Chambered Anilox Coating System for Soft Touch and UV Matte (in addition to standard Kompac Coating System)

Optional Die-Cutting, Perfing, or Creasing

Automatic Stream Feeder accepts pallets/dollies right from your digital or offset press (No “hand” loading means it is the perfect solution for variable data or sequential jobs)

Handles substrates up to 22” x 32” (560mm x 800mm), 22” x 30” (560 x 762mm) in Anilox Mode

Coat/Prime at up to 6000 sheets per hour

System includes the Kompac High Pile Pallet/Dolly Stacker, handles 34”(86cm) lift

Optional IR Dryer (or Duplex IR Dryers). Patented Short-wave intensity bulbs with Air Curtain

2-Minute Coating Change (with standard Kompac)

Available Die-Cutting, Perfing, or Creasing

REQUEST INFO

Perfect Solution For Digital Printers, Offset Printers, Commercial Packaging & Converters

HP Indigo | Xerox | Konica Minolta | Océ | Presstek DI | Xeikon | Ricoh | Kodak | Canon | KBA | FujiFilm & more

Kompac to Highlight Anilox and Soft Touch Coating at Xeikon Cafe

The team will highlight Kompac’s new chambered anilox system, how easy it is to run Soft Touch, and switch between coatings suitable for a large variety of applications.

During the event, Xeikon owners and those considering acquiring a Xeikon press, will be able to speak to team members from Kompac and find out about how the digital printers and UV/aqueous coating technology can be paired to create more efficient workflows and provide new opportunities for everyone from inplant printers to label and packaging converters alike.

Suitable for both cut-sheet and web applications, these solutions provide a host of opportunities for Xeikon users looking to increase their offering with UV/aqueous spot and flood coating.

These solutions can be for both cut-sheet and web applications, and provides a host of opportunities for Xeikon users looking to increase their offering with UV/aqueous spot and flood coating.

See for yourself!

See how the EZ Koat 20 Plus was placed inline with a Xeikon Digital Press to create a productive workflow.

About Xeikon Café

Xeikon Café North America is a learning event offered by Xeikon and its Aura partners, offering the opportunity to understand, evaluate and experience digital production. It provides the tools for commercial & in-plant printers and label & packaging converters in the U.S. and Canada to make informed business decisions. Through demonstrations, presentations, workshops and discussions, participants receive first-hand actionable information and advice on industry innovations and trends.

Request Info

NEW FROM KOMPAC: Chambered Anilox for Soft Touch & Matte Coatings

Why Only Run One Coating, When You Can Run Many?

Users can now easily run a full spectrum of coatings including: high gloss, gloss, semi gloss, satin, matte, soft touch and more - all on one machine! The NEW Kompac Chambered Anilox Roller System makes it easy to run more difficult-to-run coatings like matte and soft touch. Changeover between systems takes minutes!

For Quality Soft Touch and Matte Coating Finishes

The Kompac Chambered Anilox Roller System allows users to easily apply soft touch and matte coatings to sheets or web. The air tight handling of coating runs aqueous, matte and soft touch coating without drying and breaking down.

Chambered anilox co-exists with standard coating unit

Ideal for HP Indigo, Xerox, Canon, Ricoh, Konica Minolta, Xeikon, Offset, and more!

Available for the EZ Koat 15+, 20+ and 30+ flood coating systems in web or cut sheet configuration

Available for the Kwik Finish 32 flood and spot coating system

Can be retrofitted into existing EZ Koat Plus models

A full spectrum of finishes. Made easy.

The standard system operates with no coating recirculation and two-minute coating cleanup. To apply a more complex finish, simply engage the anilox system, where air tight liquid handling allows for the application of matte and soft touch coatings with ease. External coating feed and return lines circulate coating directly from the coating bucket, with no internal tanks or lines.

Proprietary servo-driven technology delivers a quality finish, with the same compact footprint and low maintenance operation Kompac has always offered. System can be field installed to most existing EZ Koat models.

Want to coat a substrate with Soft Touch?

Kompac Anilox Is The Cost Effective Solution!

Get More Info…

Kompac Appoints New Distributor for Poland and Surrounding Area

Kompac, manufacturer and supplier of UV/aqueous priming and coating systems, is pleased to announce they’ve appointed Scorpio Sp. z o.o. as their newest distribution partner for Poland and surrounding area.

Based in Lodz, Scorpio is one of the leading distributors of machines and materials for the graphic arts industry in Poland, and will offer full sales and support for Kompac’s complete line of sheet fed and roll to roll coating solutions. The cooperation between the companies results from Kompac’s growth strategy in Europe, and Scorpio's plans to broaden their offering in the post-press segment.

Pictured L to R: Thomas Hayes, President of Kompac, and Krzysztof Pisera, Business Development Director of Scorpio, standing with a Kwik Finish 32 UV & aqueous coating system.

Krzysztof Pisera, Business Development Director at Scorpio, said “we see considerable potential for the roll-to-roll and spot coaters in our area, and Kompac’s coating solutions fit these expectations well. This partnership will allow us to provide our customers direct access to the latest UV and aqueous coating technology for off-line and online finishing production in the graphic arts industry.”

“The appointment of Scorpio will greatly enhance access to these systems in Europe, as they have an extensive background in offset, flexography, and digital printing - which is perfect for Kompac’s coating solutions,” said Thomas Hayes, President of Kompac Technologies. “Their extensive knowledge and history within the print industry was a key factor in the decision-making process and we believe that they will be a valuable partner within our distribution network.”

For more information, please email sales@kompactech.com

Above: Product demonstration of the Elite 10 Label Coater at Scorpio’s facility in Poland