NEW Onyx 30 UV/AQ Coating System

Kompac has announced the release of the ONYX 30, a high production priming and coating system for the application of UV, Aqueous, Primer/Sapphire, and specialty coatings to a wide variety of substrates. The nearline finishing unit provides commercial printers and in-plant facilities a flexible, cost-effective way to prime, flood, and spot coat sheets up to 22” x 32” (560mm x 800mm) wide at speeds up to 6000 sheets per hour. The first install of the ONYX 30 took place in August with a US-based prepress & print shop with multiple HP Indigo Digital Presses in operation.

Kompac Releases New Coating & Priming System

The ONYX 30 is an exciting nearline coating, priming, and die cutting system, providing a quick and easy way to apply UV, Aqueous, Primer/Sapphire, and specialty coatings to a wide variety of substrates. From ultra thin paper to plastics, card stock and lenticular; whether digital output or offset, each job will have the visual appeal, lasting durabiilty, protection and rub-resistant finish that your customers expect. Flood or Spot coat, the Kompac Onyx 30 is the most flexible, cost-effective coating system on the market today!

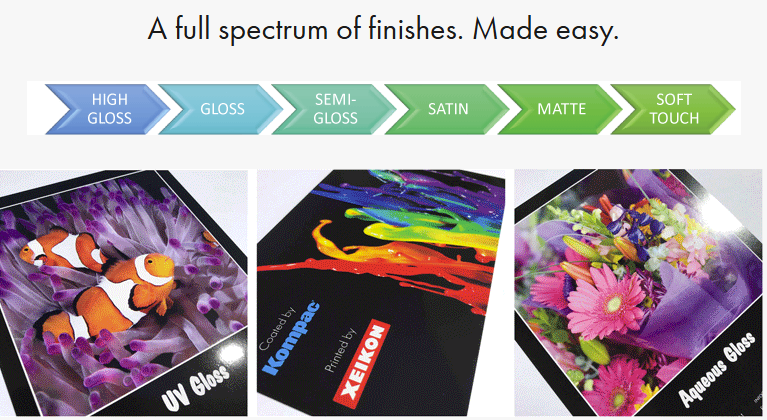

NEW FROM KOMPAC: Chambered Anilox for Soft Touch & Matte Coatings

Users can now easily run a full spectrum of coatings including: high gloss, gloss, semi gloss, satin, matte, soft touch and more - all on one machine! The NEW Kompac Chambered Anilox Roller System makes it easy to run more difficult-to-run coatings like matte and soft touch. Changeover between systems takes minutes!