What do YOU choose? Lamination or UV and Aqueous Coating?

Watch how easy it is to enhance product packaging using Soft Touch for the surface, and then spot coat using high gloss to add dimension and shine! Spot coat...

UV Spot Coating for Print and Packaging

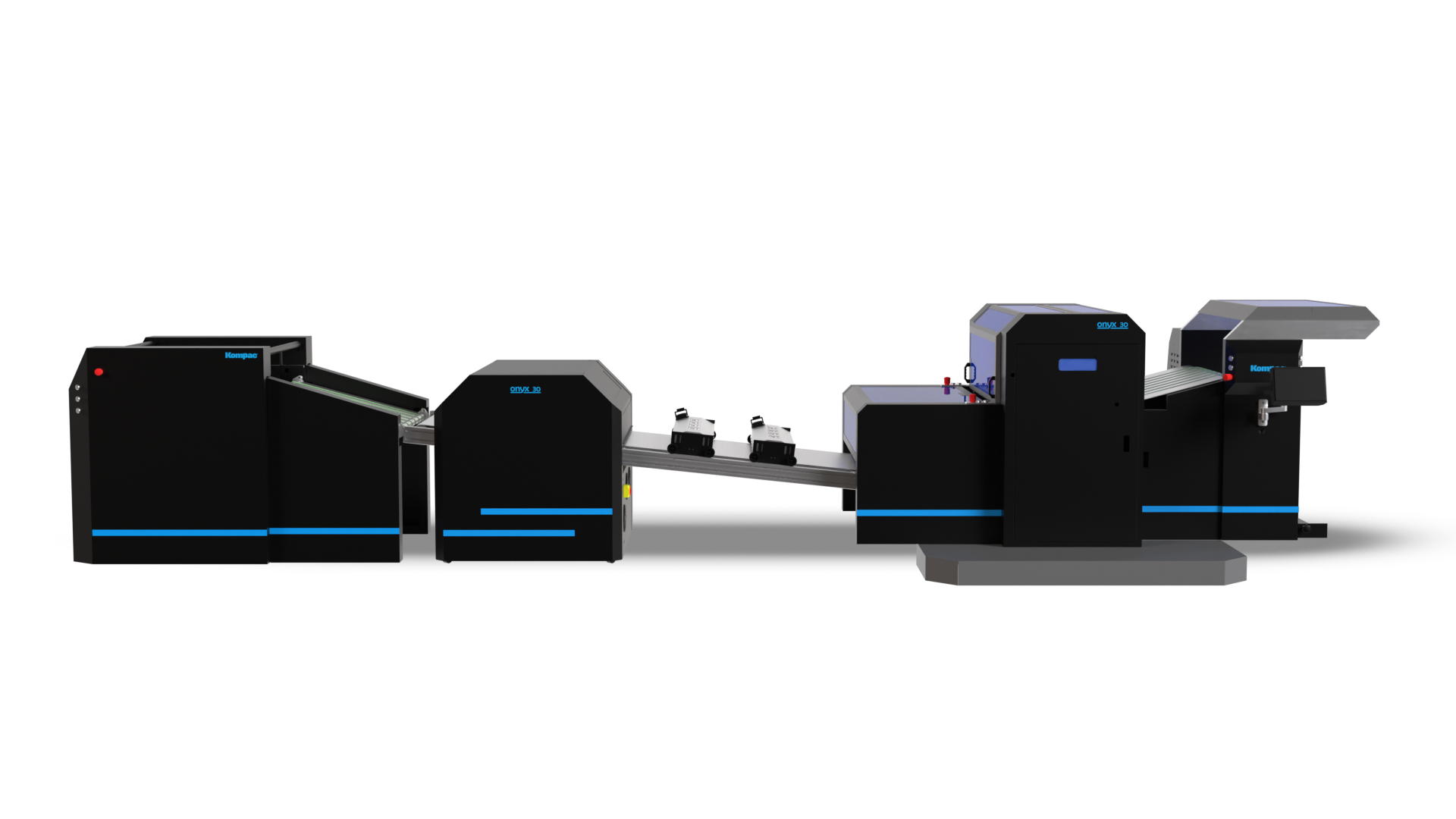

Kompac's Onyx 30 gives users the ability to apply Primers, UV, Aqueous, and Specialty Coatings to stock ranging from 3-30pt (60-600gsm), at speeds up to 6000 sheets per hour! Die-cut, perf and crease to produce outstanding finished products!

NEW EZ Koat 2040 and 3040 Feeder and Stacker for 40" Sheets!

The EZ 2040/3040 Feeder & Stacker are production-level equipment that allows greater throughput on the Kompac EZ Koat 20 and 30 UV & aqueous coating systems. This coating machinery can now fit an incredible 20”x40” (50.8cm x 101.6cm) sheet with no loss in speed. It also accepts pallets (32” lift) to avoid hand-loading of sheets, and make the pre- and post press finishing a breeze!

NEW FROM KOMPAC: Chambered Anilox for Soft Touch & Matte Coatings

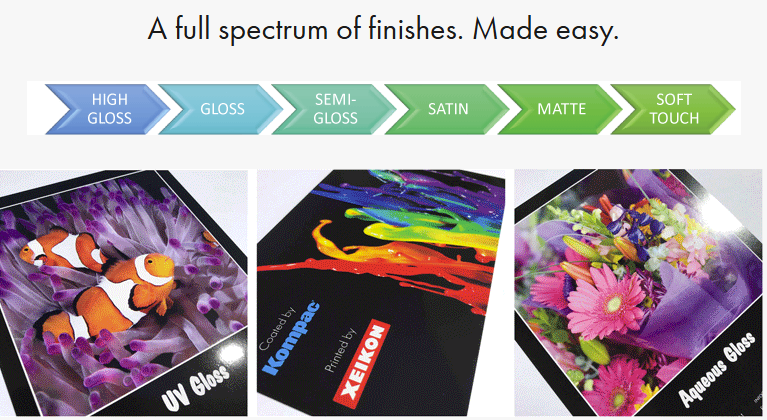

Users can now easily run a full spectrum of coatings including: high gloss, gloss, semi gloss, satin, matte, soft touch and more - all on one machine! The NEW Kompac Chambered Anilox Roller System makes it easy to run more difficult-to-run coatings like matte and soft touch. Changeover between systems takes minutes!

Next Up: HP Indigo MasterClass

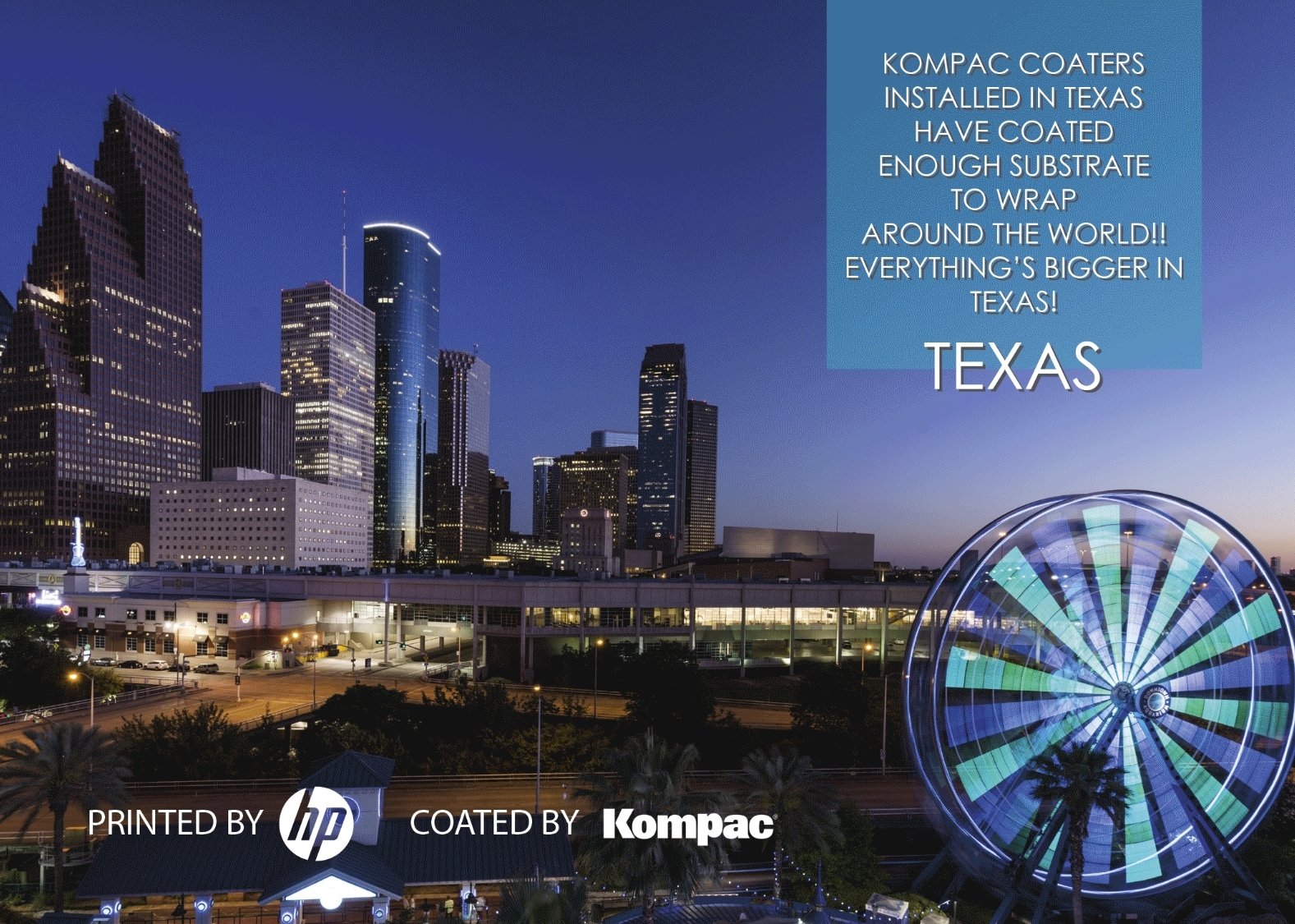

If you want to find out how Kompac’s coating solutions pair with HP’s print technology, or set up a time to discuss send us an email sales@kompactech.com

Kompac Appoints New Distributor for Poland and Surrounding Area

Based in Lodz, Scorpio is one of the leading distributors of machines and materials for the graphic arts industry in Poland, and will offer full sales and support for Kompac’s complete line of sheet fed and roll to roll coating solutions. The cooperation between the companies results from Kompac’s growth strategy in Europe, and Scorpio's plans to broaden their offering in the post-press segment.