NEW Onyx 30 UV/AQ Coating System

Kompac has announced the release of the ONYX 30, a high production priming and coating system for the application of UV, Aqueous, Primer/Sapphire, and specialty coatings to a wide variety of substrates. The nearline finishing unit provides commercial printers and in-plant facilities a flexible, cost-effective way to prime, flood, and spot coat sheets up to 22” x 32” (560mm x 800mm) wide at speeds up to 6000 sheets per hour. The first install of the ONYX 30 took place in August with a US-based prepress & print shop with multiple HP Indigo Digital Presses in operation.

Kompac Releases New Coating & Priming System

The ONYX 30 is an exciting nearline coating, priming, and die cutting system, providing a quick and easy way to apply UV, Aqueous, Primer/Sapphire, and specialty coatings to a wide variety of substrates. From ultra thin paper to plastics, card stock and lenticular; whether digital output or offset, each job will have the visual appeal, lasting durabiilty, protection and rub-resistant finish that your customers expect. Flood or Spot coat, the Kompac Onyx 30 is the most flexible, cost-effective coating system on the market today!

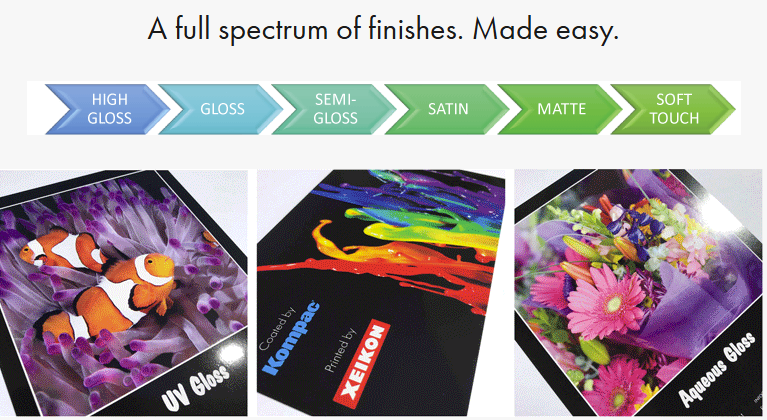

NEW FROM KOMPAC: Chambered Anilox for Soft Touch & Matte Coatings

Users can now easily run a full spectrum of coatings including: high gloss, gloss, semi gloss, satin, matte, soft touch and more - all on one machine! The NEW Kompac Chambered Anilox Roller System makes it easy to run more difficult-to-run coatings like matte and soft touch. Changeover between systems takes minutes!

Next Up: HP Indigo MasterClass

If you want to find out how Kompac’s coating solutions pair with HP’s print technology, or set up a time to discuss send us an email sales@kompactech.com

Kompac Appoints New Distributor for Poland and Surrounding Area

Based in Lodz, Scorpio is one of the leading distributors of machines and materials for the graphic arts industry in Poland, and will offer full sales and support for Kompac’s complete line of sheet fed and roll to roll coating solutions. The cooperation between the companies results from Kompac’s growth strategy in Europe, and Scorpio's plans to broaden their offering in the post-press segment.